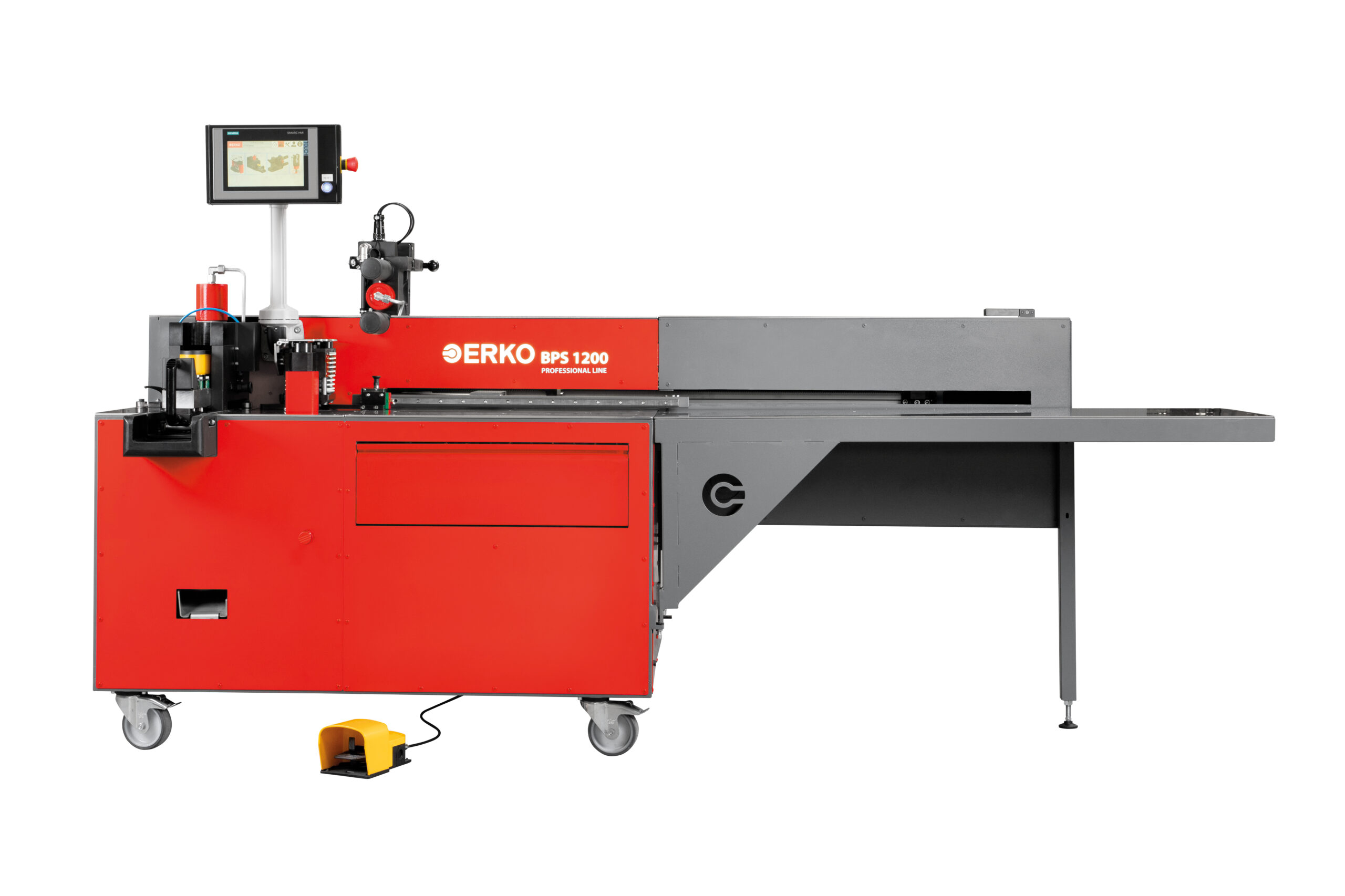

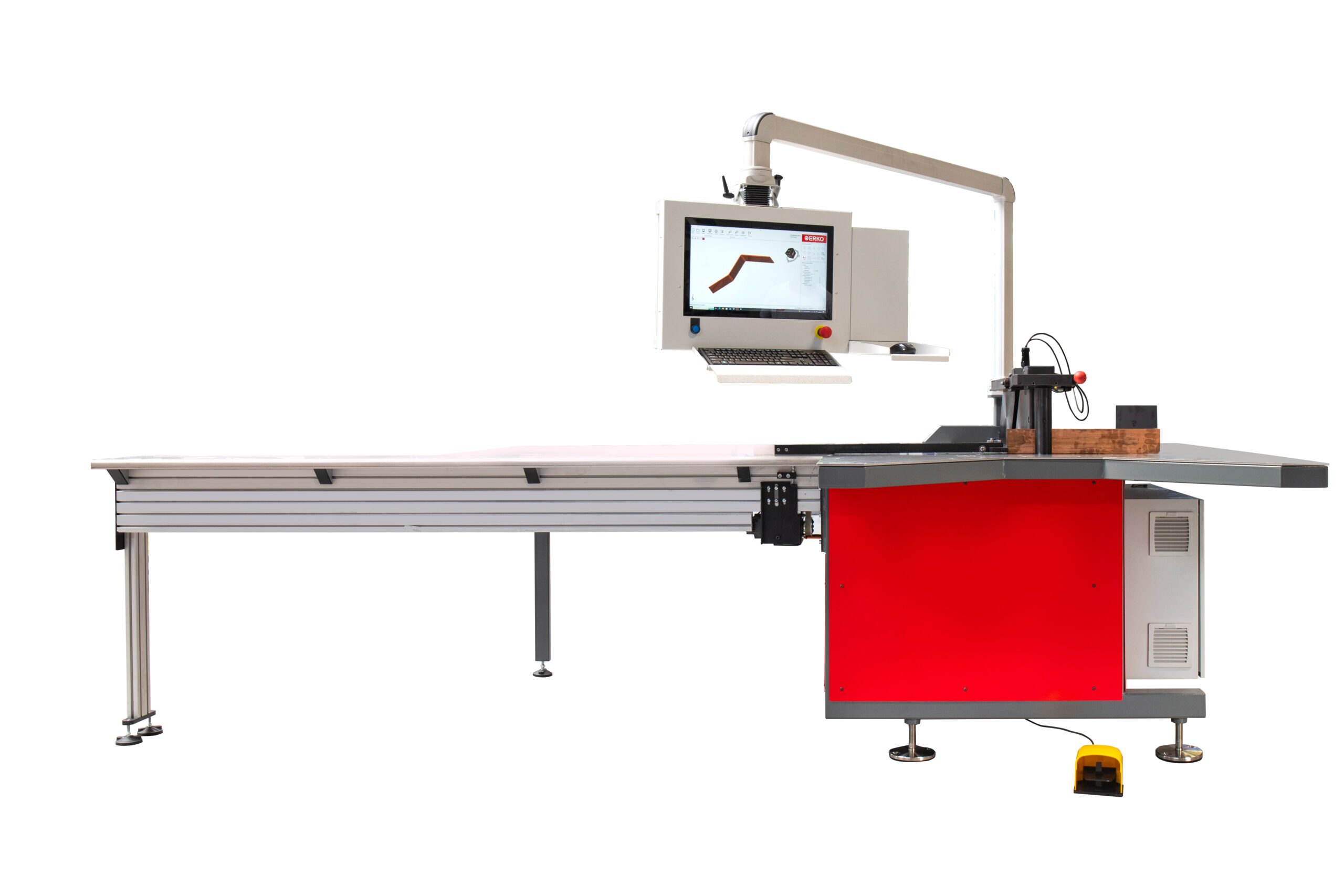

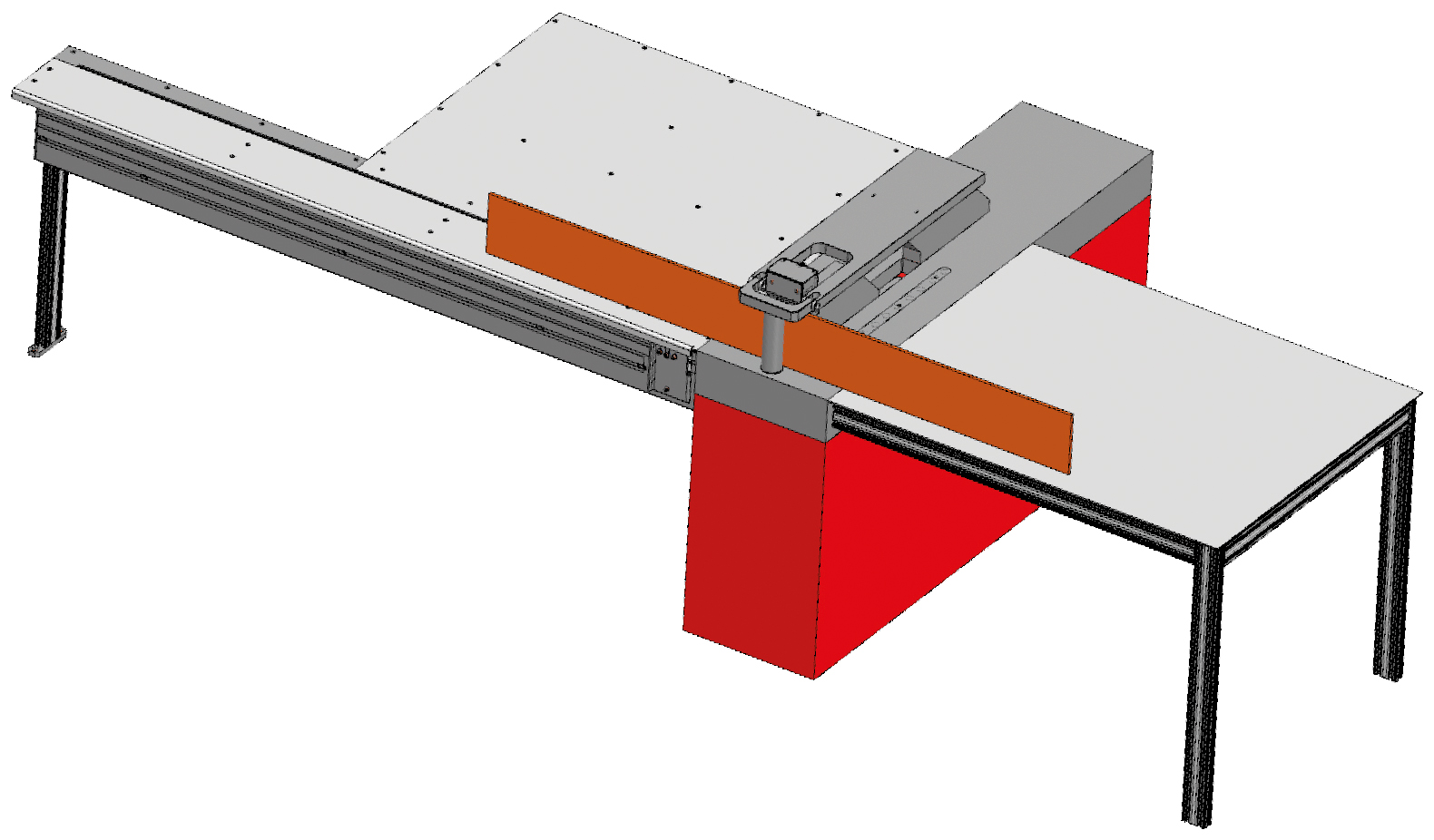

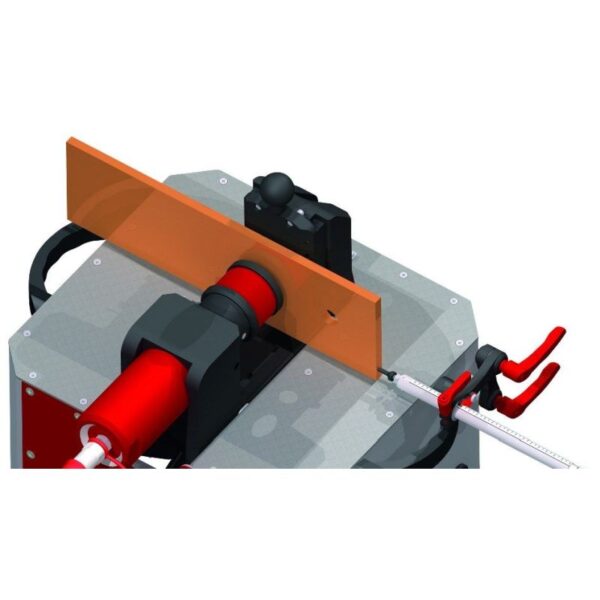

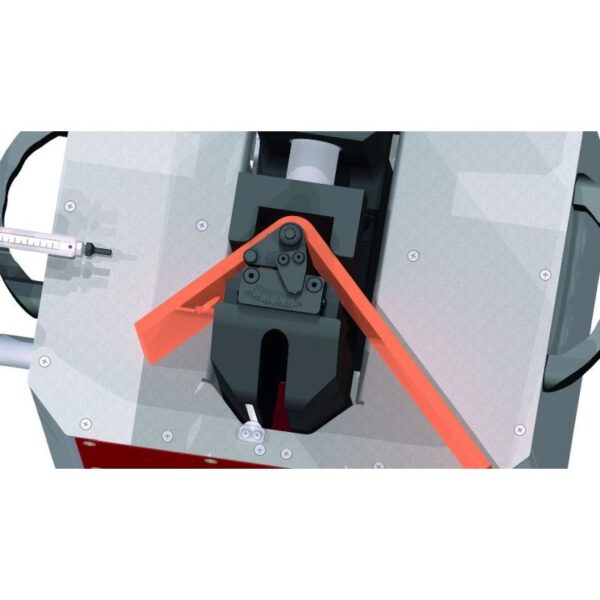

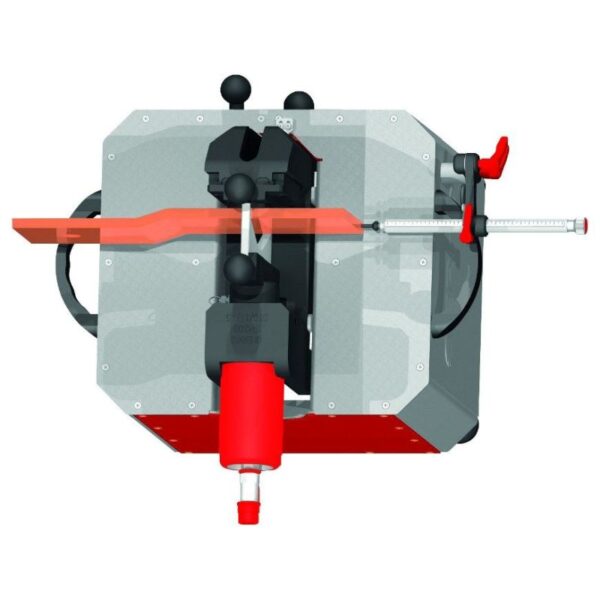

SH 300 Busbar Processing Station

Station for cutting, hole punching, bending and offsetting Al and Cu busbars as well as inserting nuts:

• width range: 30 ÷ 125 mm

• thickness range 5 ÷ 12 mm

• bending angle range 15° ÷ 90°

Special features:

• equipped with an adjustable bending angle indicator (graduation rate of the resolution is 5°, measurement does not include the elasticity of the busbar)

• equipped with a bumper with scale (adjustment ruler range is 200 mm, accuracy of 1 mm)

• body height adjustment (accuracy of 1 mm)

• burr-free round and oval holes punching

• burr-free busbars cutting

• standard set for inserting nuts SH 307, SH 303

Works with:

H 800 hydraulic pump and AH 100, AH 500, AH 550, AH 500L hydraulic units (need to be ordered separately).

Overall dimensions (LxWxH): 550x540x430 mm;

Weight with standard equipment 57 kg;

Force: 150 kN;Pressure: 630 bar

- VIDEO

- TECHNICAL DATA

| Equipment | Type | SH 300 |

| Insert for bending (angle indicator) | SH 301 | x |

| Insert for bending with limit switch | SH 301-K | x |

| Insert for cutting | SH 305 | x |

| Insert die for busbars offsetting. Standard dimensions 12; 10; 8; 6; 5 | SH 306 | x |

| Round hole punch (standard dimensions according to the catalog) | SH 303 | x |

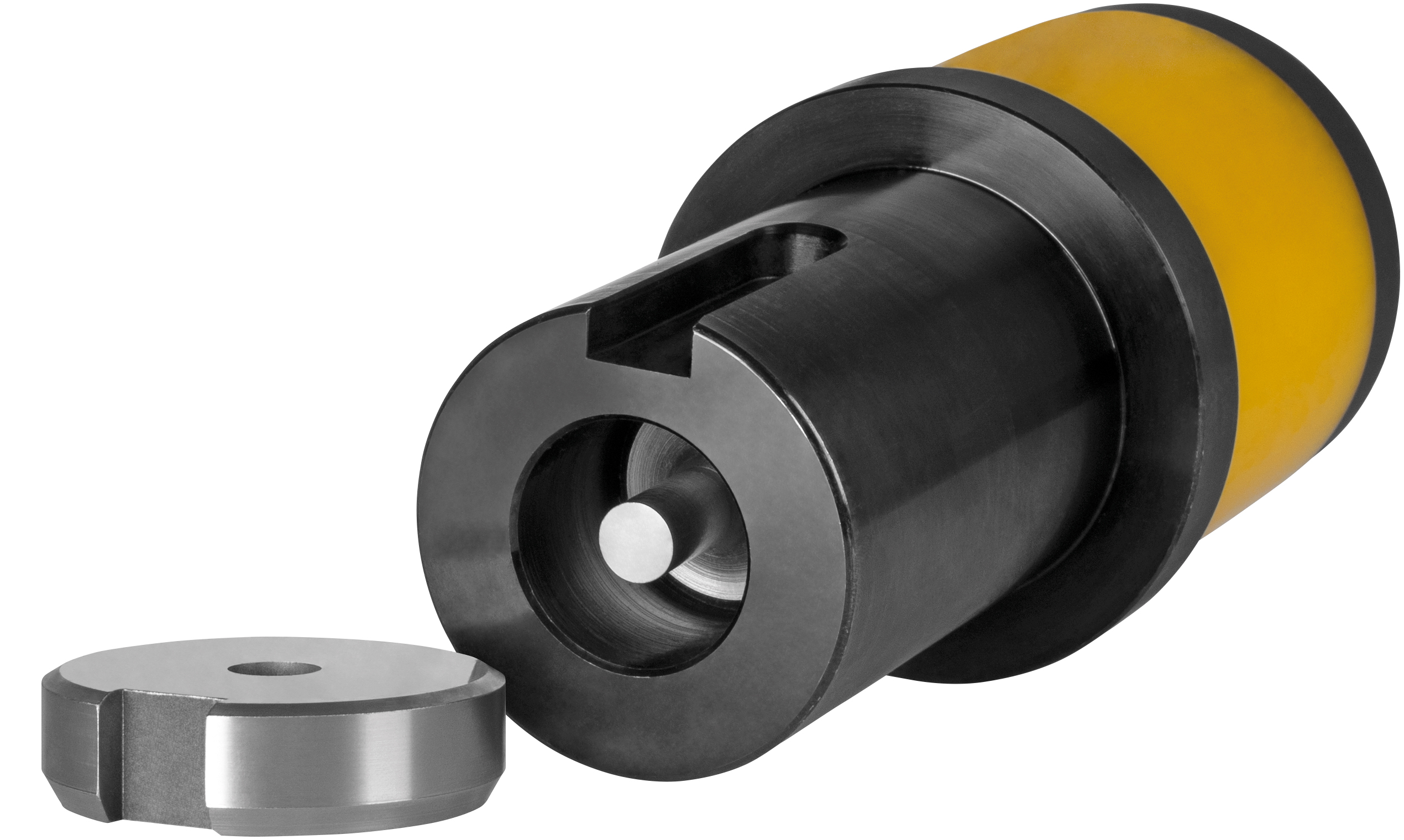

| Adapter for punches SH 303 and SH 304 | SH 303-03 | x |

| Oval hole punch (standard dimensions according to the catalog) | SH 304 | x |

| Rectangular hole punch (dimensions according to order: maximum up to 21 mm diagonal, side not shorter than 6,6 mm) | SH 309 | x |

| Insert die for inserting nuts (applies to ERKO nuts, others on request) | SH 307 | x |

x – additional equipment on request