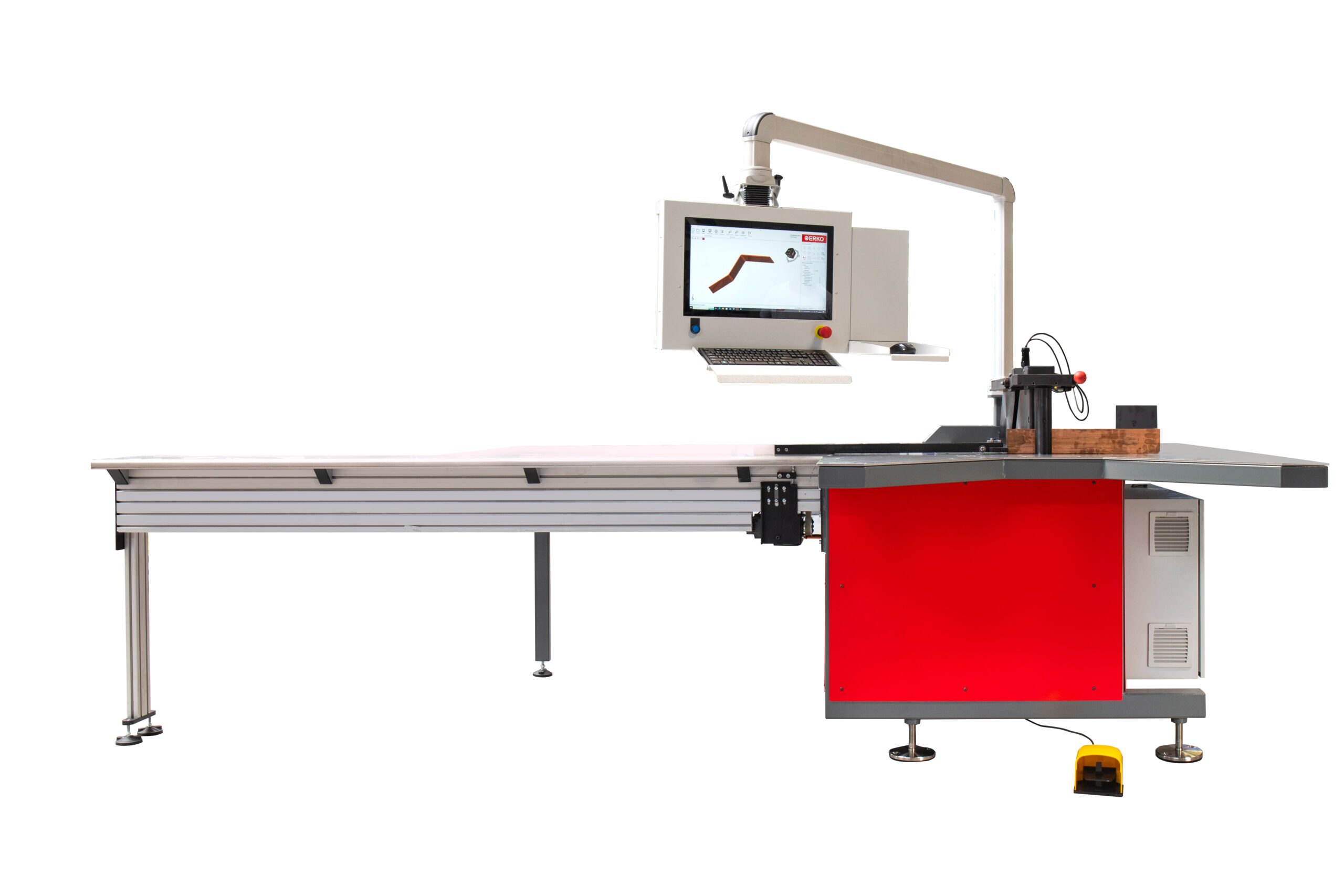

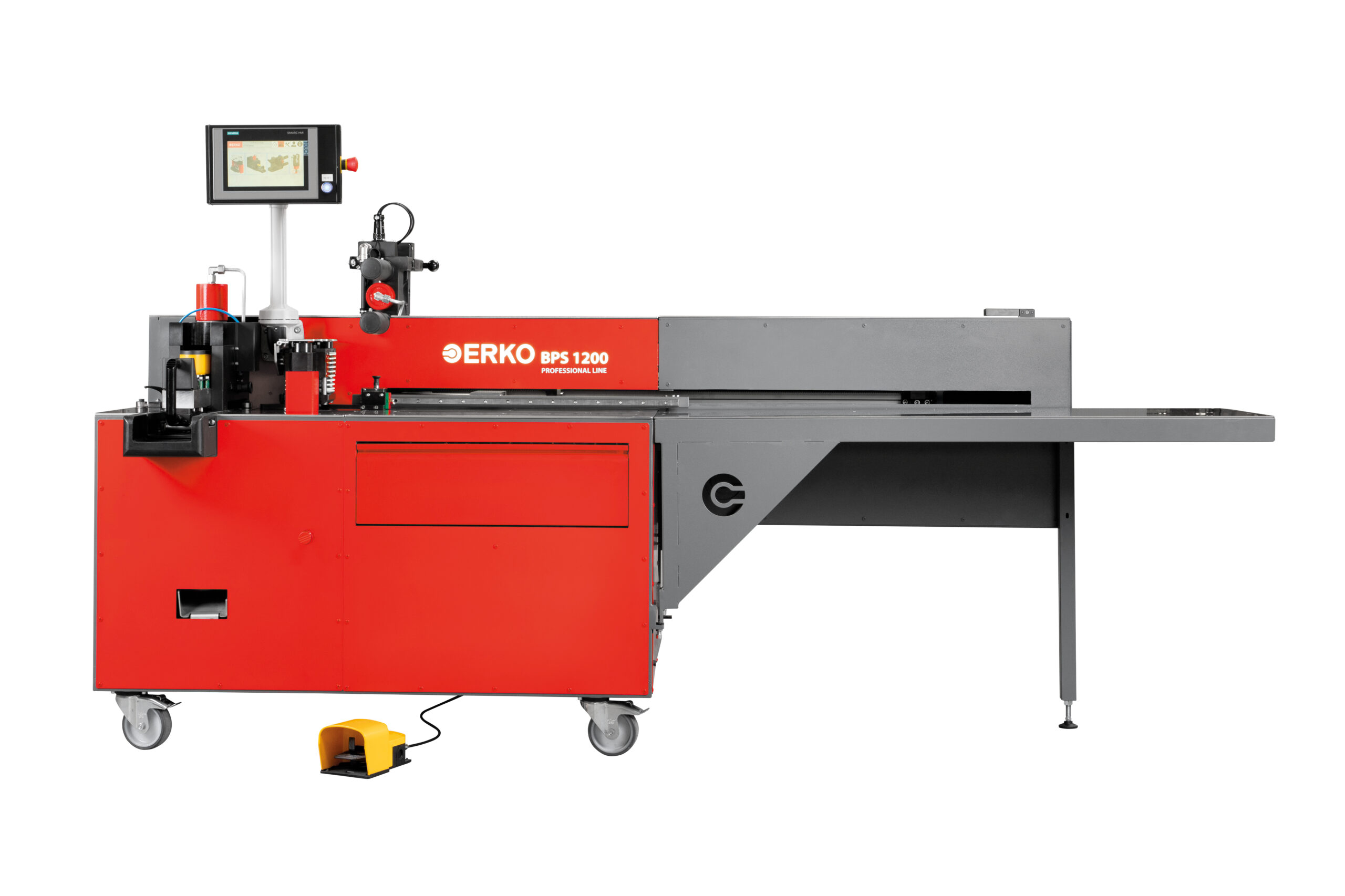

BPS 1200 busbar processing station

Station for precise cutting, bending, and punching of Al, Cu, and Al-Cu busbars:

• busbar width 20 ÷ 125 mm

• busbar thickness 5 ÷ 12 mm

• bending angle 5° ÷ 90°

Total dimensions(DxSxW): 3800x2000x1700 mm

Weight with standard equipment: 650 kg

Working pressure: 630 bar

Power supply: 3 x 400V/230V AC; Electric power: 2kW

Distinctive features:

• increasing the speed of the busbar production process by up to 30% compared

to the previous generation

• it works with innovative software for designing busbars

• possibility to use the innovative computational algorithm

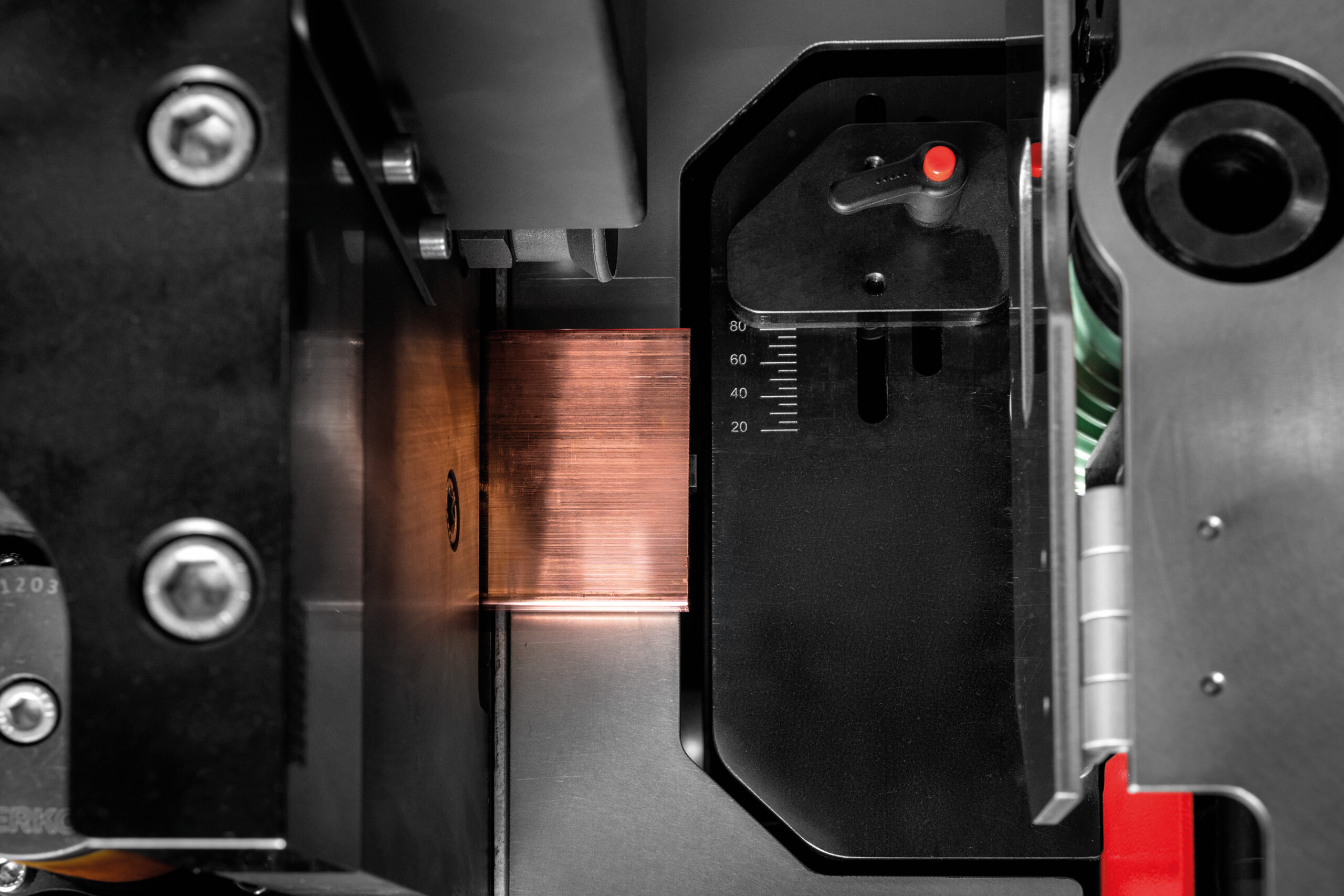

• automatic positioning of the measuring ruler during punching, bending, and cutting

operations (based on procedures or previously entered data)

• measuring ruler position accuracy 0 1mm for cutting and punching of processed

busbars (up to 2 000 mm) and bending (up to 1 600 mm)

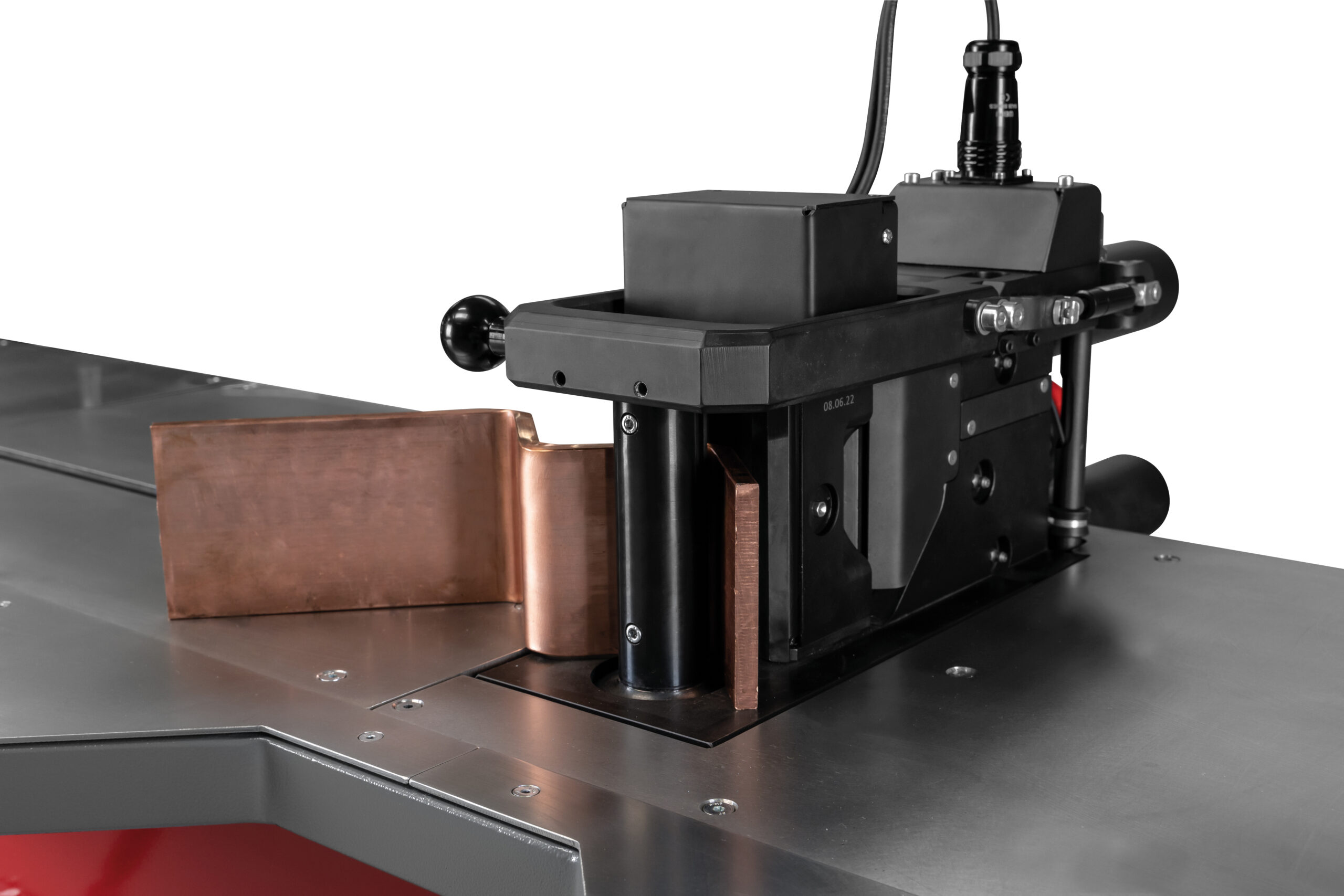

• possibility of bending in an “L” shape for busbars up to 10 mm thick at a distance

of 40 mm from the edge (fig 1)

• possibility of bending in a “C” shape for busbars up to 10 mm thick at a distance

of 45 mm from the edge (fig 2

• possibility of bending in a “Z” shape for busbars up to 10 mm thick at a distance

40 mm from the edge and between the bends the bends (fig 3)

• bending angle accuracy ± 0 2° with adjustment for busbar elasticity

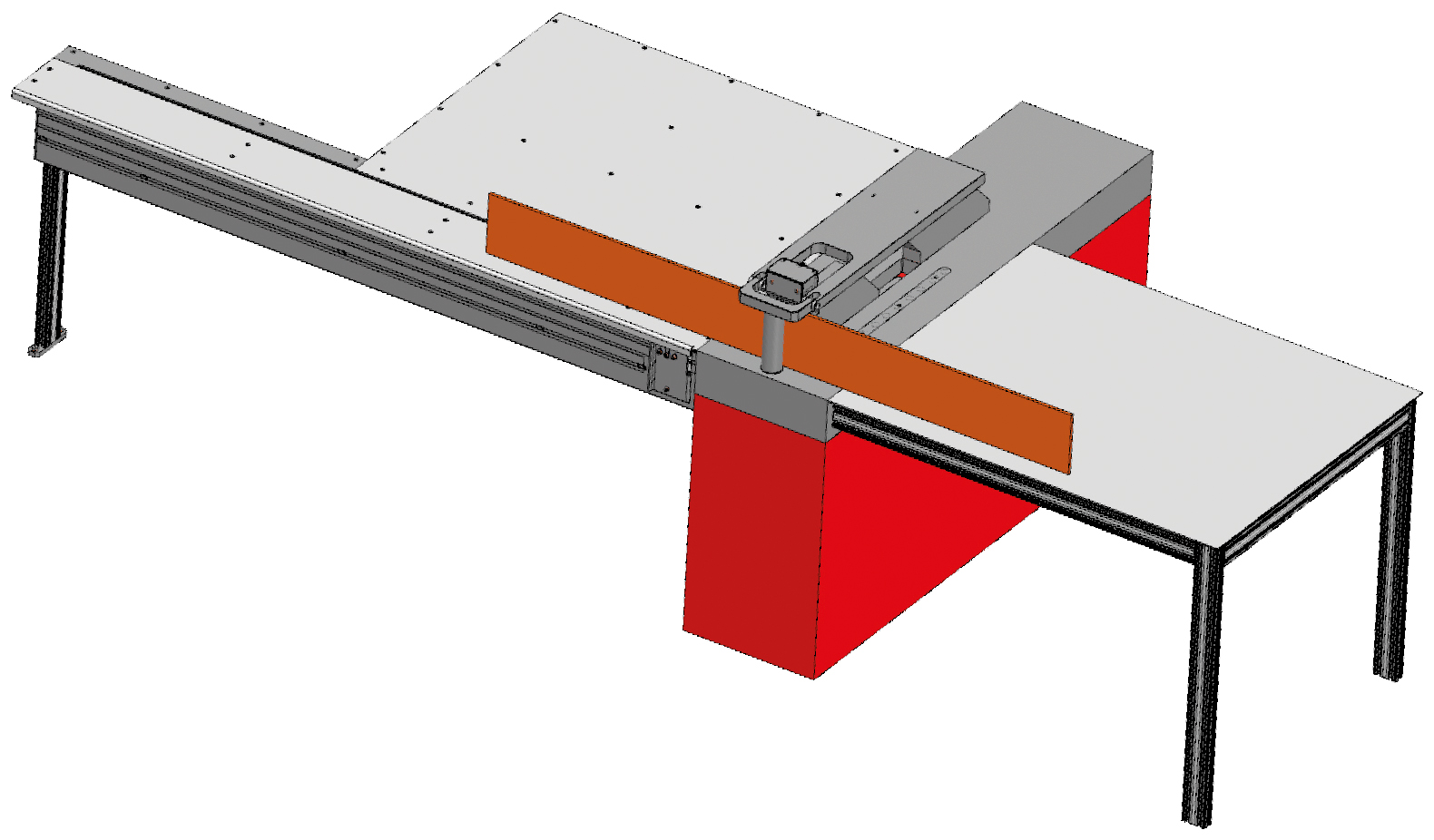

• guillotine can be hidden under the worktop surface

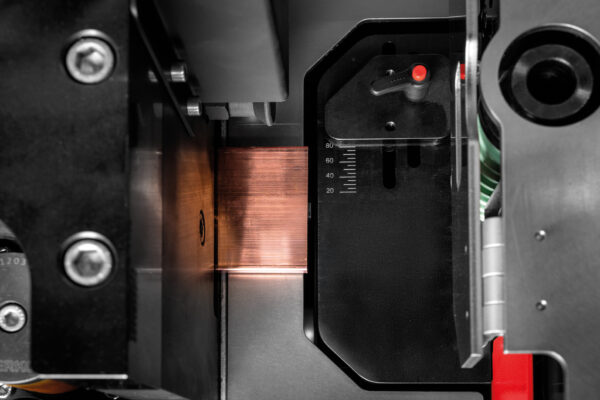

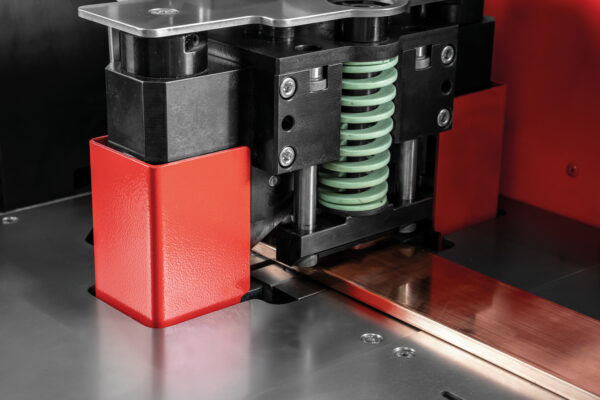

• automatic controlled press of the cut busbar

• minimum length of cut busbar: 30 mm

• burr-free and no surface deformation busbar cutting

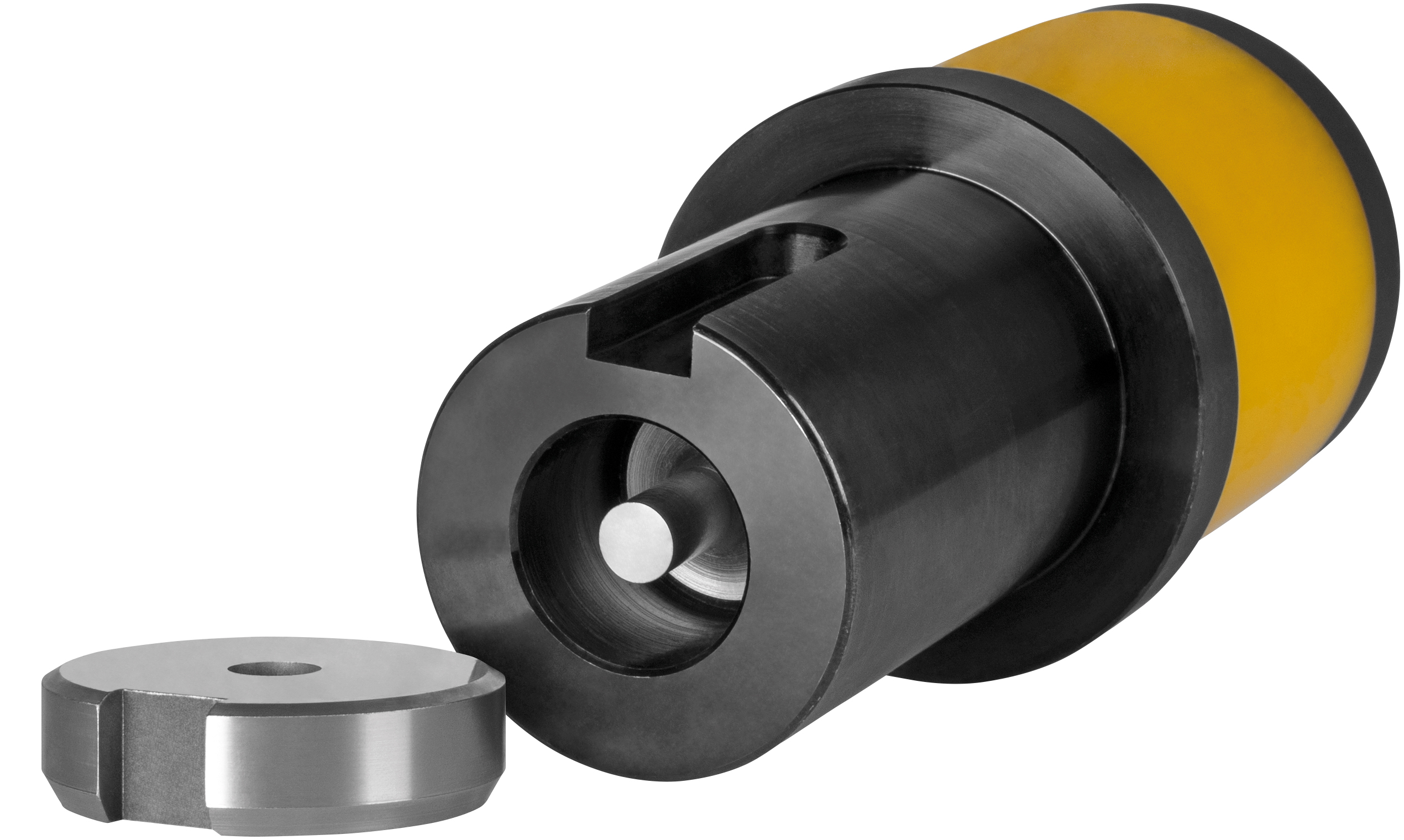

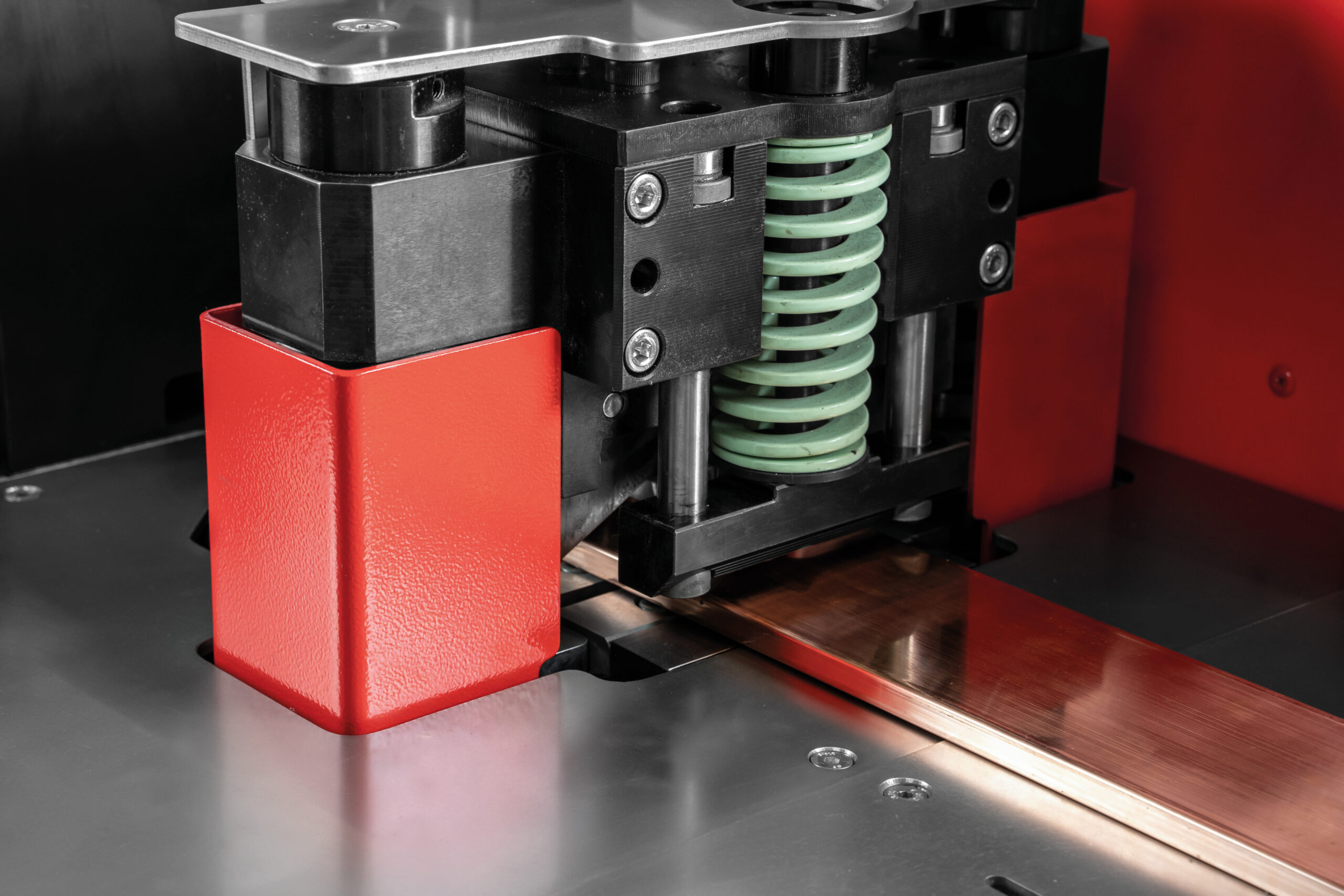

• a movable cassette which allows installing of four punches and eliminates the need

for retooling

• burr-free round and oval holes punching

• possibility of saving and recalling busbar processing procedures

• built-in reliable and efficient hydraulic drive

• additional connections for other tools offered by ERKO (hydraulic hose with a PM

quick coupler)

• maintained mobility of the machine

• possibility of remote diagnostics