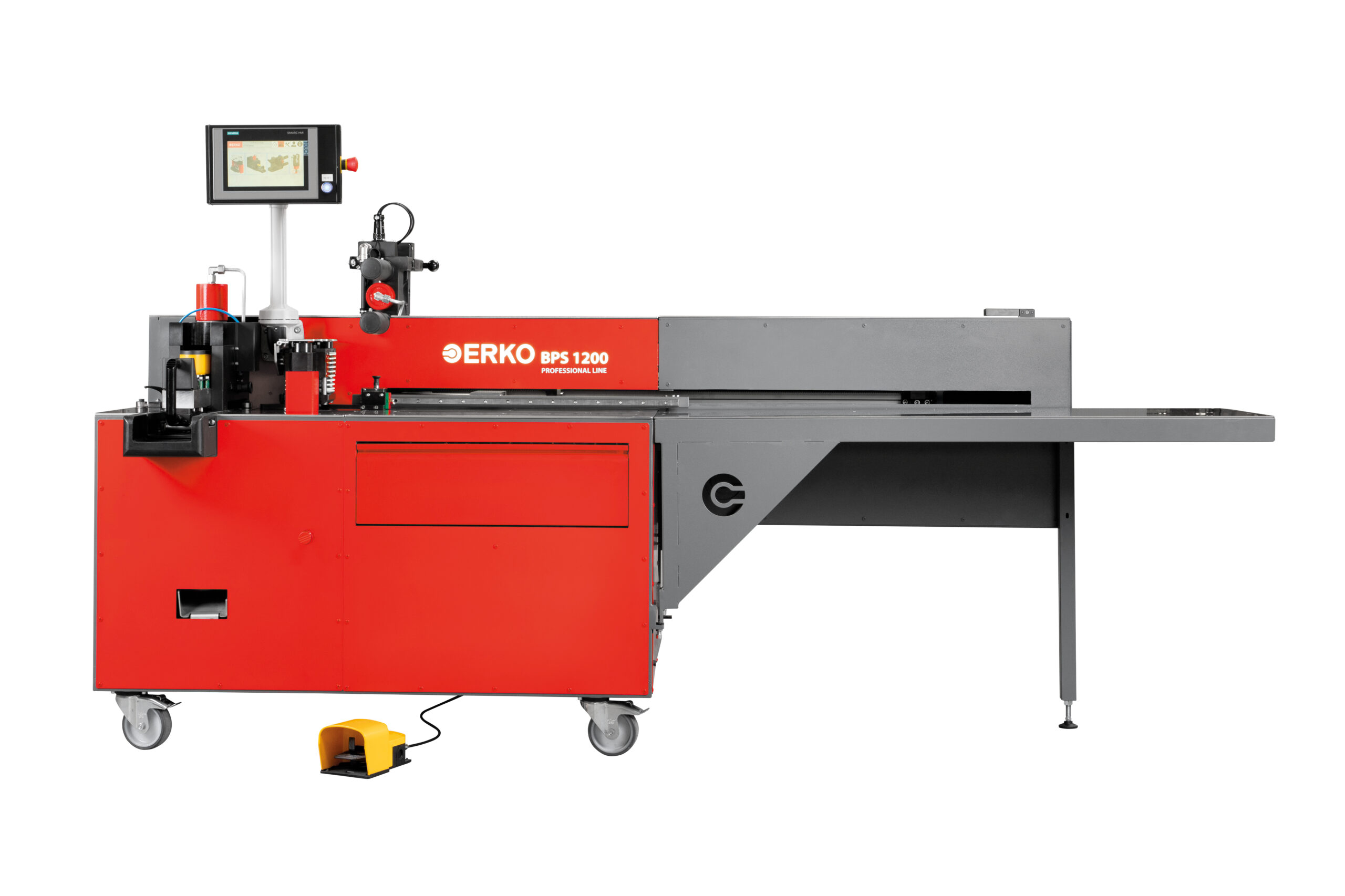

BPS-P busbar processing station

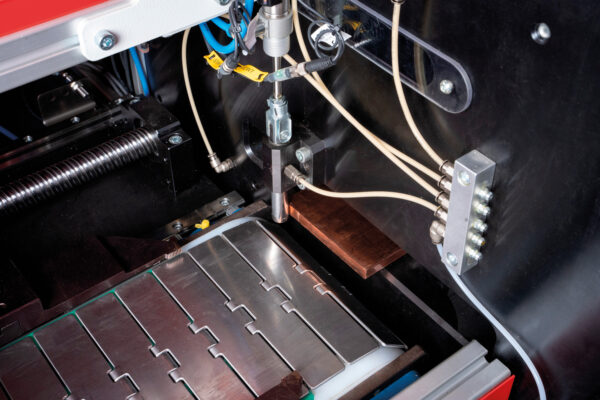

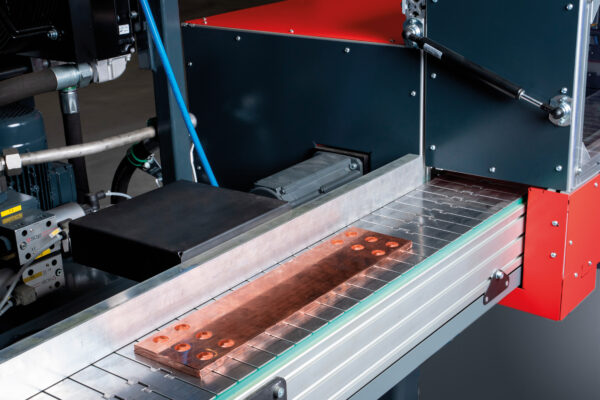

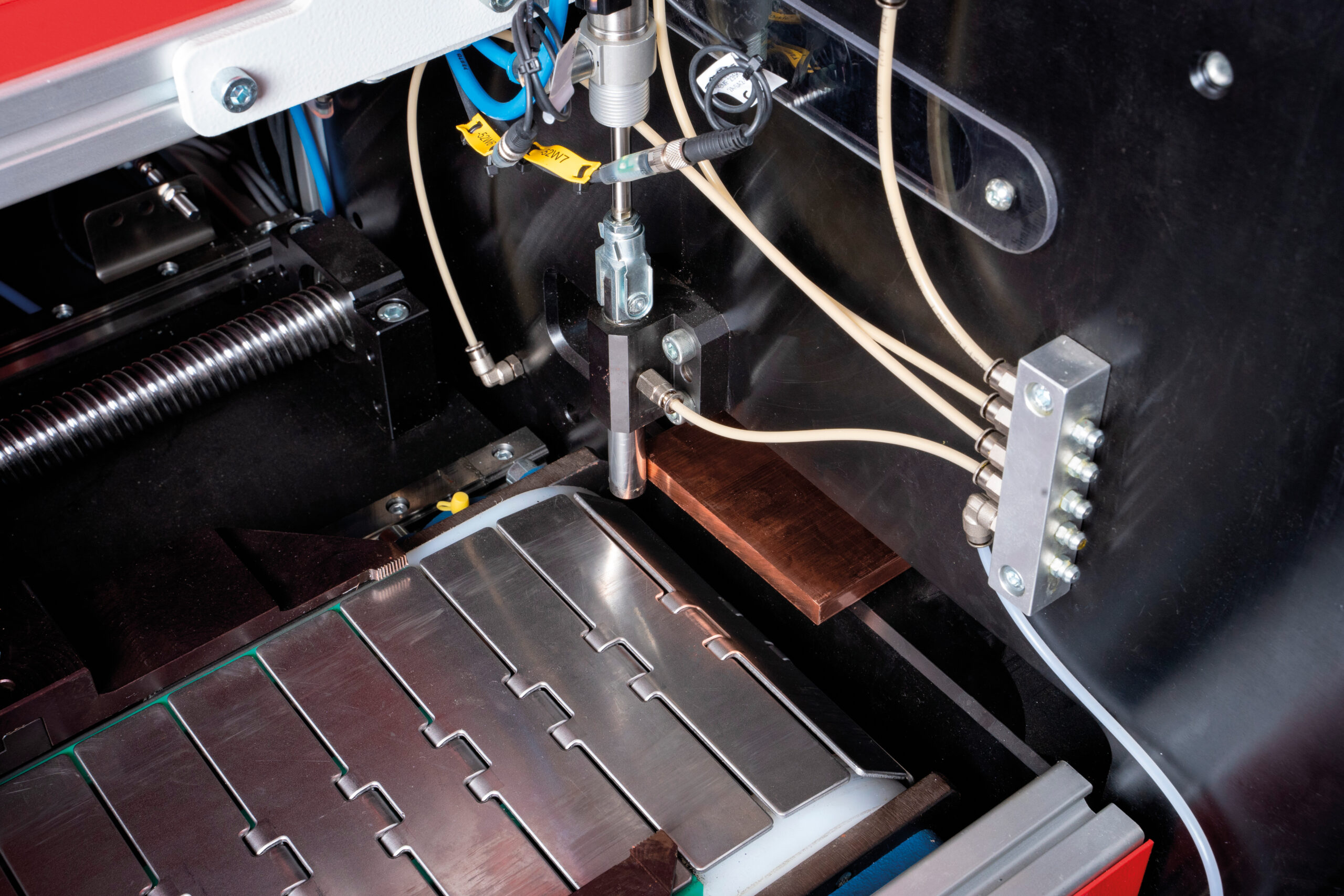

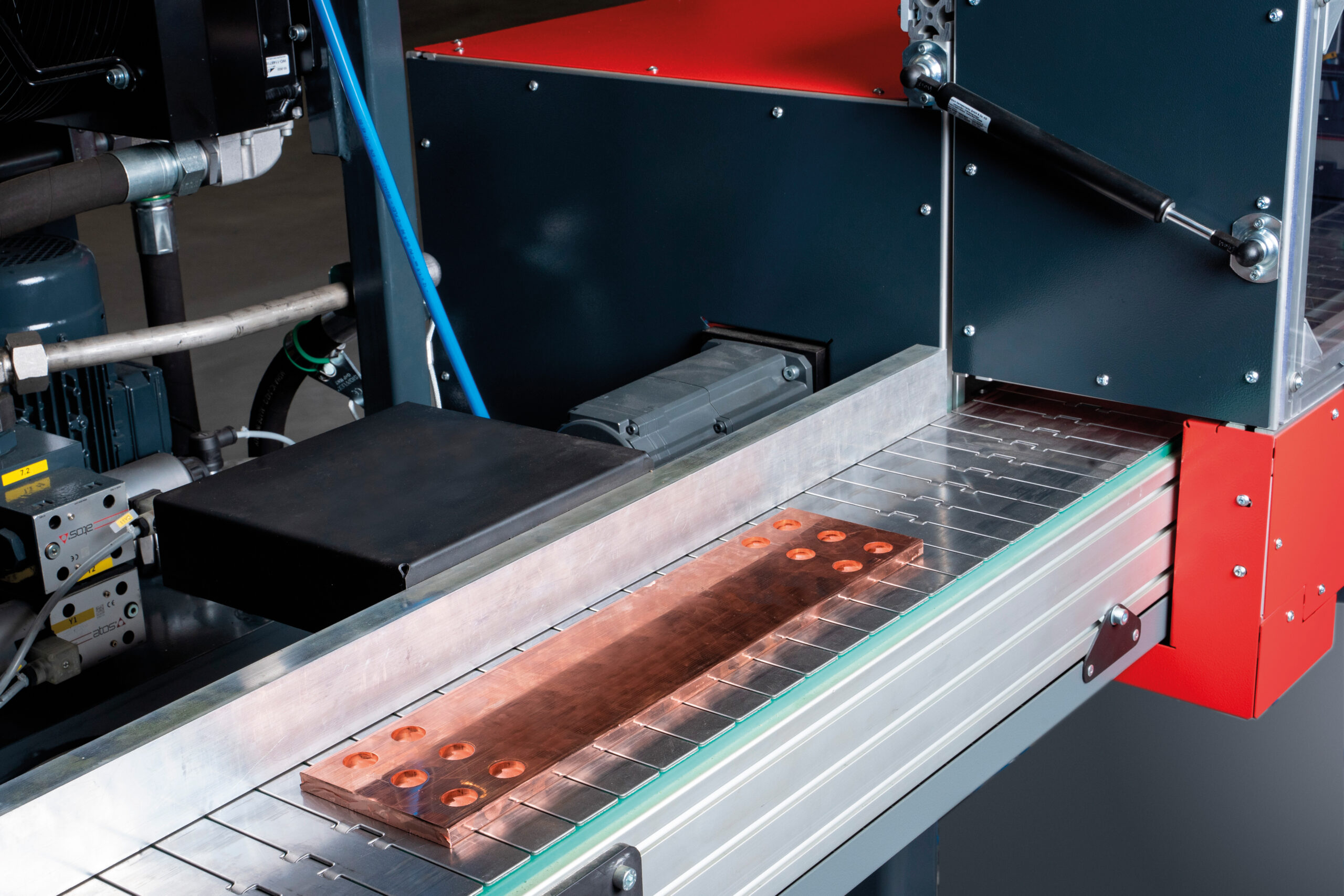

Station for precise cutting, bending, and punching of Al, Cu and Al-Cu busbars:

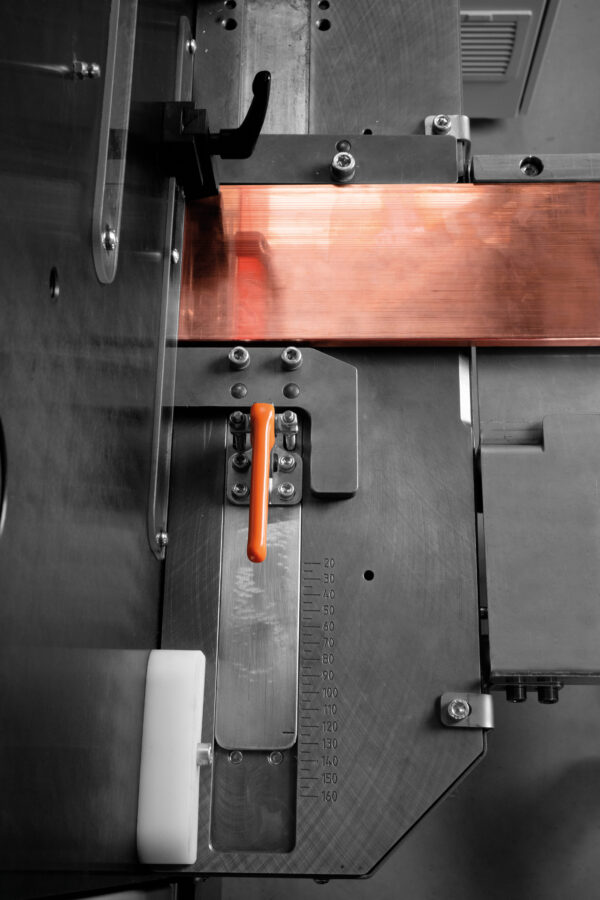

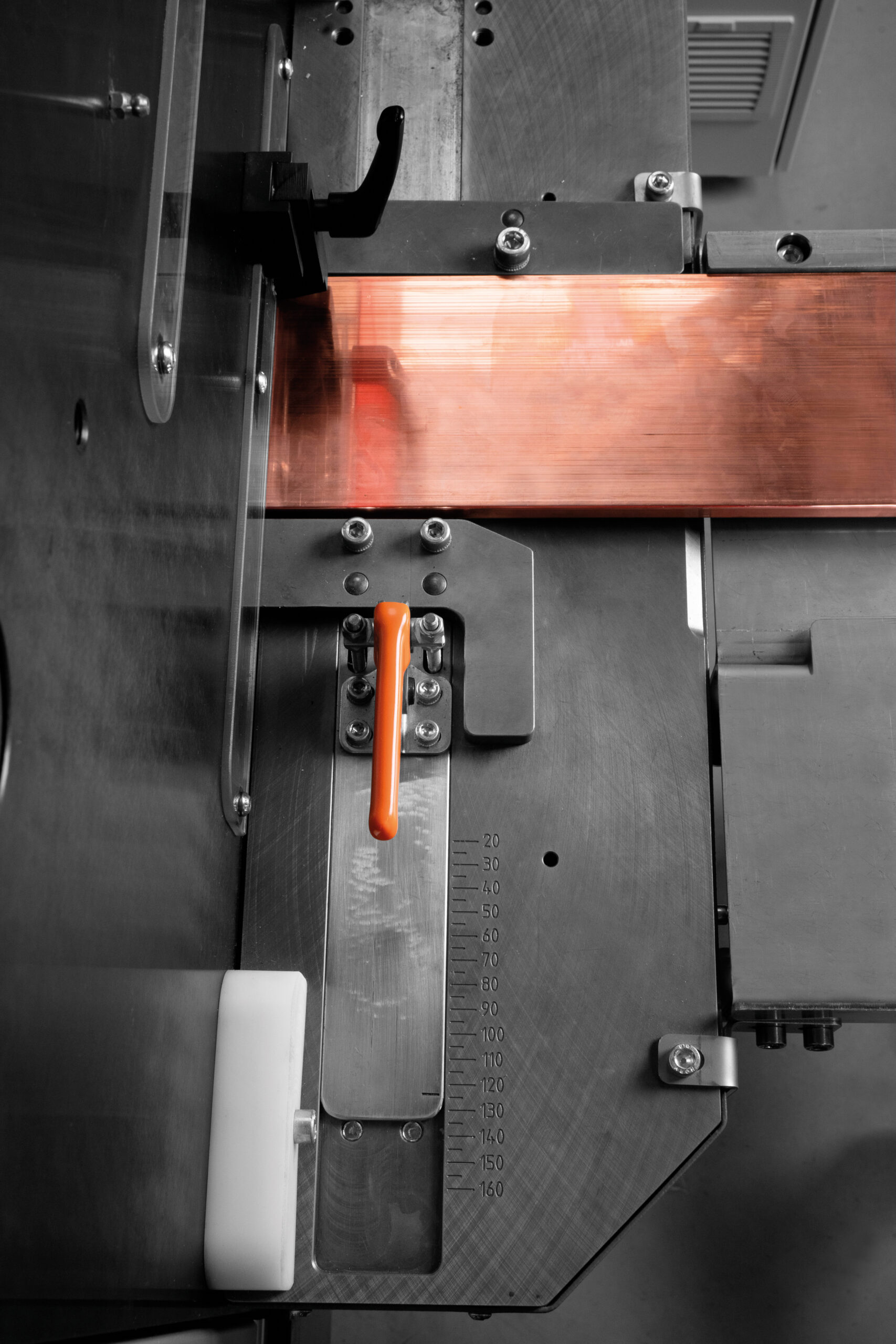

• busbar width 20 ÷ 160 mm

• busbar thickness 3 ÷ 15 mm

• maximum length of the cut busbar: 4 metres

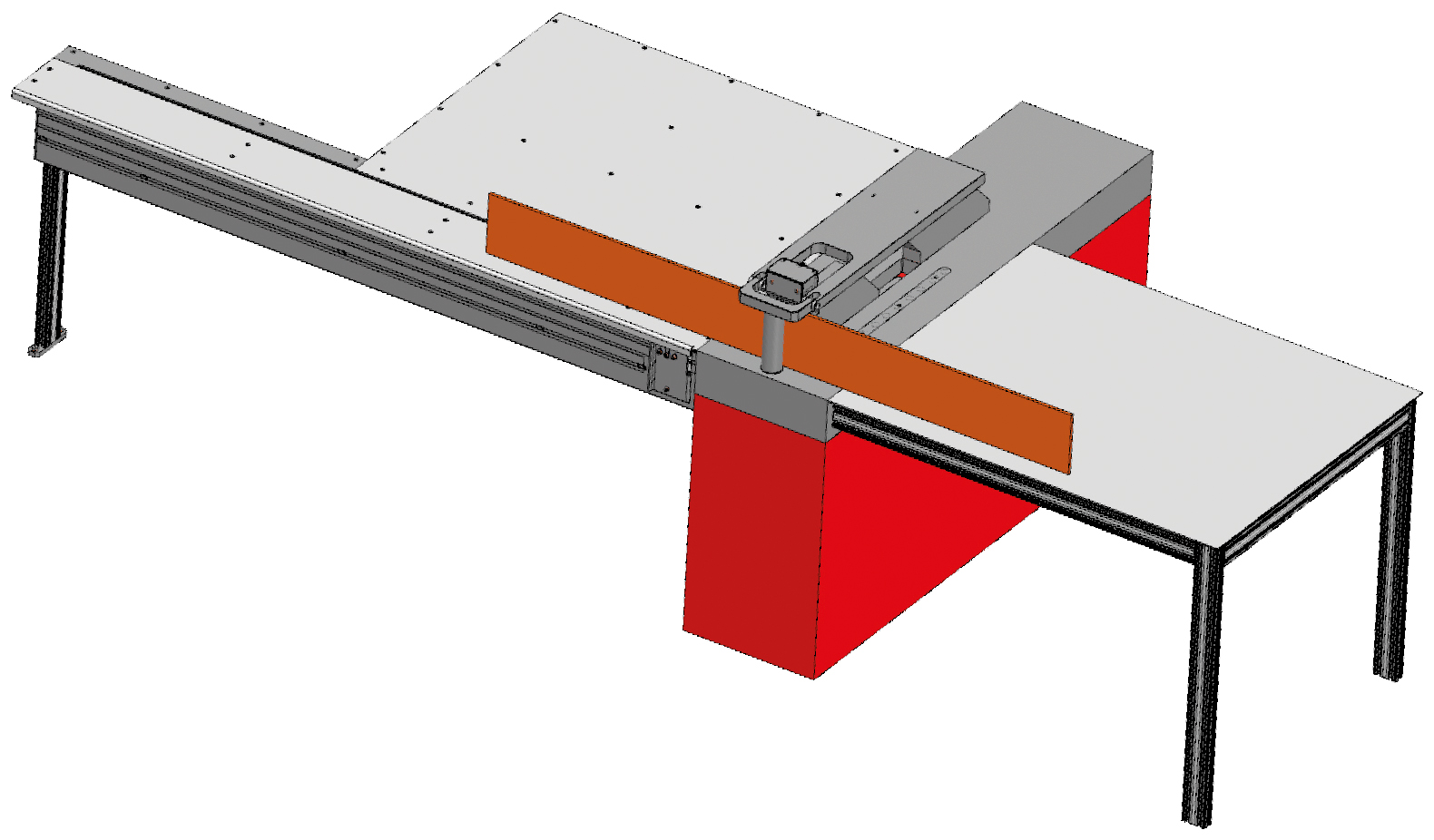

Total dimensions(DxSxW): 7253x3639x2000 mm

Weight with standard equipment 3200 kg with the hydraulic power pack

Working pressure: 300 bar

Power supply: 3×400/230 V AC; Electric power: 21 kW

Distinctive features:

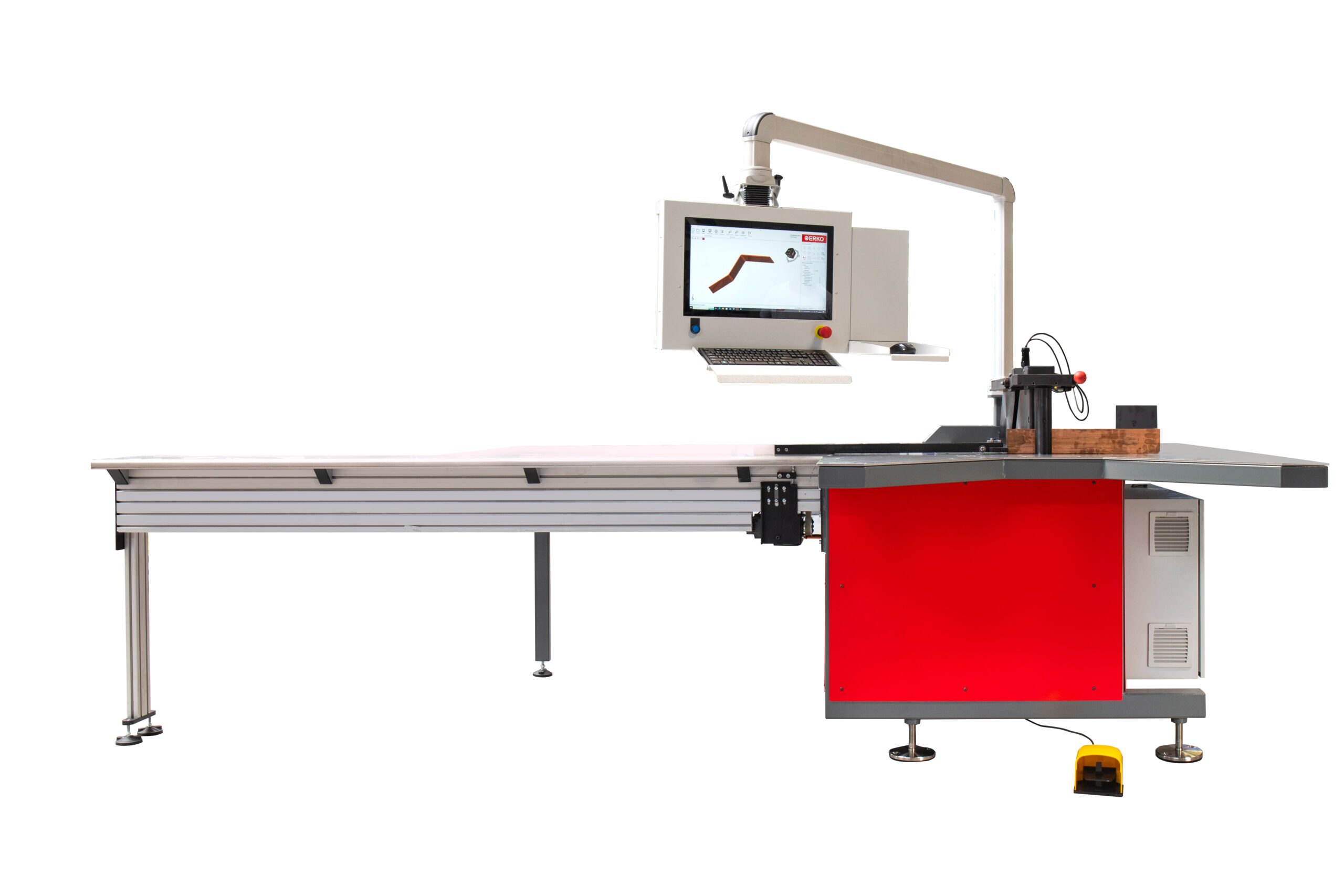

• direct work of the machine with the innovative algorithm for designing busbars

• operator support covers designing, technology, and processed material

• application providing possibility to print the designed busbar in 2D and 3D views

• possibility of adaptation to work in the production line

• control system performing CNC functions

• designing busbars directly on the machine with a 3D visualisation and generating

the developed length of a bent busbar

• equipped with a 22-inch operator’s touchscreen with the multitouch function

• dedicated to high-performance and precise serial production

• busbar feeding ruler accuracy of the position: 0 1 mm

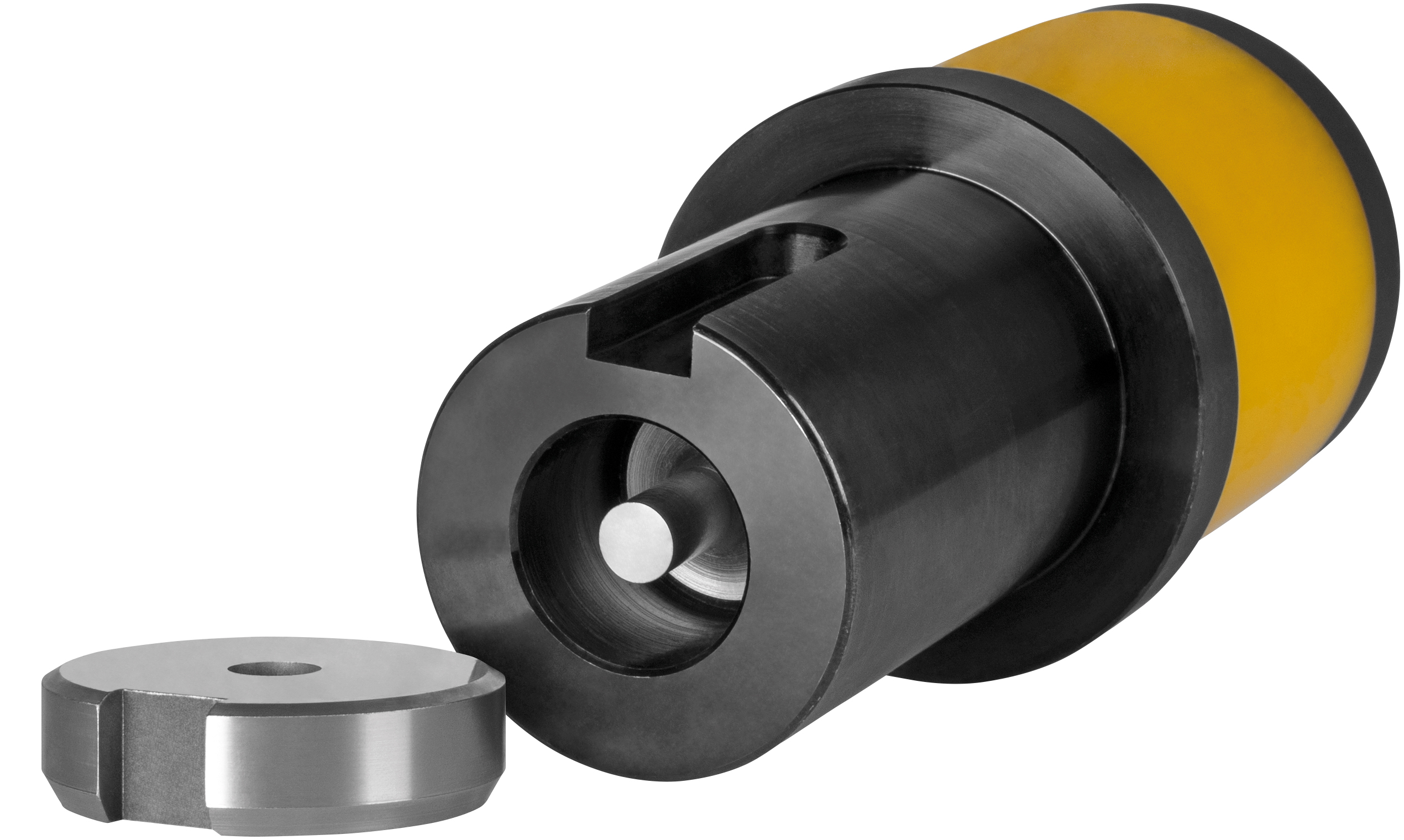

• movable cassette which allows installing of five punches and eliminates the need

for retooling

• burr-free round, oval, and custom-designed holes punching

• minimum length of cut busbar: 25 mm

• burr-free and no surface deformation, single operation busbar cutting

• possibility of saving designs on a network drive

• possibility of using designs developed on desktop software

• possibility of extending the machine with additional machining tools

(e.g custom-made punches)

• remote software update, including material base

• it facilitates use for people with disabilities

• stable, stationary structure

• force of pressure 300 kN