Materials applied in production of cable terminals and connectors.

Cu tubular terminals and connectors – Electrolytic copper Cu-ETP (E-Cu) according to PN-EN 13600 and PN-EN 13601

Cu terminals made according to DIN 46228 part 1 and 4 – Copper Cu-ETP/Cu-DHP

Cu strip-cut terminals – Electrolytic copper Cu-ETP according to PN-EN 1652

Al terminals and connectors – Aluminum EN AW 1370 / EN AW 1050A (EAl 99,5/ Al 99,5) according to PN-EN 573-3

Tabs and receptacles – Brass according to PN-92/H-87025

Insulation – Polyamide – the material of a high thermal (from -40ºC to +125ºC) and shock resistance. – Polyamid VO – nonflammable material, class VO /UL 94, (to individual order).

Cover – Tin 99,90 according to EN610

Copper single conductor with condensed wires

Cables, which have a working strand made of copper rolled wire with trapezoid section, are called cables with condensed wires.

It is a strand with tight arranged wires, which compose into a very hard core, comparable with a section of a solid material.

Crimping forms:

(e.g. KOA, KWA, KLA).

wire of cross section of 0,5 ÷ 6mm2 (e.g. MS, TS, KOP, KNP).

re – singlestrand wire cross section in mm2, rm – multistrand wire cross section in mm2

Pressing terminals and connectors

1. Select terminal or connector appropriate for the wire.

2. Determine proper form of crimping.

3. Strip the cable to the same lenght as tubular part of terminal.

4. Before crimping the wire must be cleaned of oxides and corrosive deposits.

5. Insert the wire to the end of tubular part of terminal or to connector narrowing.

6. Choose appropriate tool and dies (check last column of terminals sizes charts)

7. Keep crimping until dies clamp or overflow valve of hydraulic drive responds

8. Crimping may be single (e.g. KOE, KOA) or multiple (e.g. KCR, KLA).

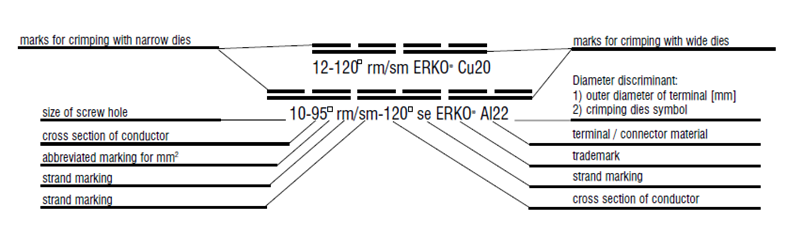

Copper and aluminum tubular terminals made according to DIN have marks for crimping as shown below (fig.):

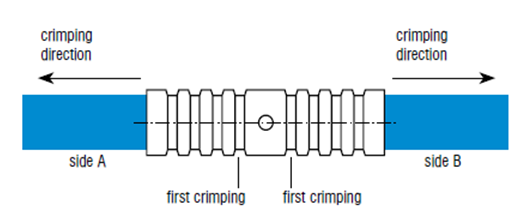

9. It is essential to keep the direction of crimping terminals and connectors as shown below (fig.):

NOTE

Tools and terminals system provided by ERKO ensures high performance throught the period of use. The use of third-party products (made in accordance with other standards) may cause much lower quality connections.

Assortment

The assortment consists over 1700 types of wire terminals and connectors for crimping on the Cu and Al cables with cross section from 0,14 mm2 up to 625 mm2. ERKO offer also contains mechanical, hydraulic and pneumatic tools dedicated for:

-

- terminal’s crimping

- cable processing

- hole punching in sheet metal and plastic

- busbar and mounting rail processing

Certificates and attestation

ERKO products meet requirements for electrical equipment, and have all necessary certificates and attestation. In general, cable lugs and connectors are produced according to DIN and PN standards. The opinion issued by the Electrotechnical Institute in Warsaw on the quality of ERKO products admit to use them in electrical devices.

Cable lugs also have the admission of Polish Ship Register to be used on ships. (Products for ships – V0 class flame retardant insulation available on request).

The company activity is based on the Quality and Environmental Management System, which has been implemented and in accordance with the requirements of ISO 9001 and ISO 14001. In 2003 ERKO products gained the GOST-R Certificate of Accordance.

We ensure professional customer service, technical assistance and efficient warranty and post warranty service.