CZELUŚNICA, 1938

A year before the beginning of World War II, Piotr Pętlak, the father of later founder of ERKO Roman Pętlak, built a smithy in Czeluśnica. Back then it was a small wooden building standing right on the front line. As a result of the war, the walls of the nearby house were shelled, and the forge was demolished.

WHERE THE HORSES WERE SHOD

Later, during communism, Piotr Pętlak bought a Lemko chimneyless thatched hut. It was disassembled and transported to Czeluśnica, where he set up a quite comfortable forge, as for those times. Years later, it turned out that history likes to surprise, because that is exactly where the first blades’ castings gate cutting for modern Pratt-Whitney Rzeszów passenger aircraft engines was performed.

FORGING CHARACTER

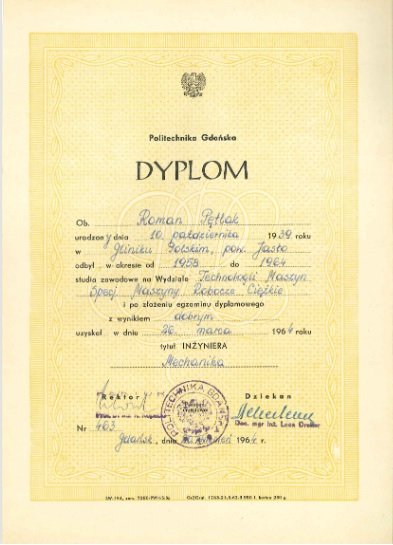

Roman Pętlak, the eldest son of Piotr, worked hard as a child, helping his parents in the fields, with farm animals, and in the smithy. Additionally, he took care of five younger siblings. He did very well at school and wanted to be a constructor. He got into the Technical School of Shipbuilding in Gdańsk (CONRADINUM), and then continued his studies at the Faculty of Mechanical Engineering at the Gdańsk University of Technology and at the Fisheries Study in Szczecin.

He endured through difficult times away from his family. Sometimes, there was not enough money for the basic needs. Already then, he promised himself that his family would have everything they need.

SETTING COURSE FOR WARMIA

Out of the love for a beautiful dentistry student of the Medical Academy, Roman Pętlak moved to Olsztyn. It was not an easy decision for an already successful engineer involved in construction of krill and fish vessels. Instead of building huge ships, he started calculating simple structures in a small local company. However, ambition and diligence spurred him to move further.

As deputy and later as technical director of OLPASZ, Roman Pętlak designed an integrated feed production and storage system, which was popularized in Poland and awarded the medal of Polish Federation of Scientific and Technical Associations. He travelled with the then Minister of Agriculture as an adviser to the USSR for negotiations with Georgia.

During martial law, Roman’s life turned upside down. For his invlovement in the Solidarity movement, he was fired from work and was blacklisted by the authorities. This excluded any possibility of employment in the city of Olsztyn and its vicinity.

JONKOWO, 1981

The Fiat 125p motor vehicle, the summer house built together with his brothers, Jan and Józef, and a modest collection of stamps inherited from his parents-in-law – this was the property that became the contribution to a new business. With the money raised, a small building was built in Jonkowo near Olsztyn, where he established the Roman Pętlak Metal Works.

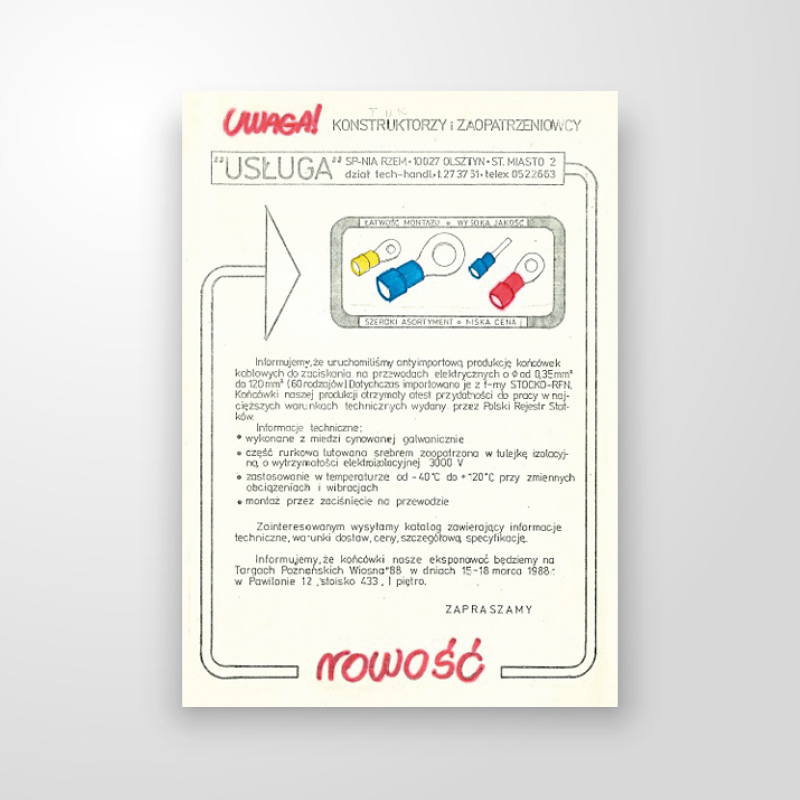

It began with the production of forks, hoes, and small furnaces for heating. From his colleagues from the shipyard, Roman learned about the need for cable terminals, which the socialist state industry was unable to produce. He took up the challenge, and despite the initial problems with access to materials and gaining permit for capitalist artisanal production, Roman Pętlak’s managed to test and certify his products for use on ships.

BUSINESS WITH A VISION

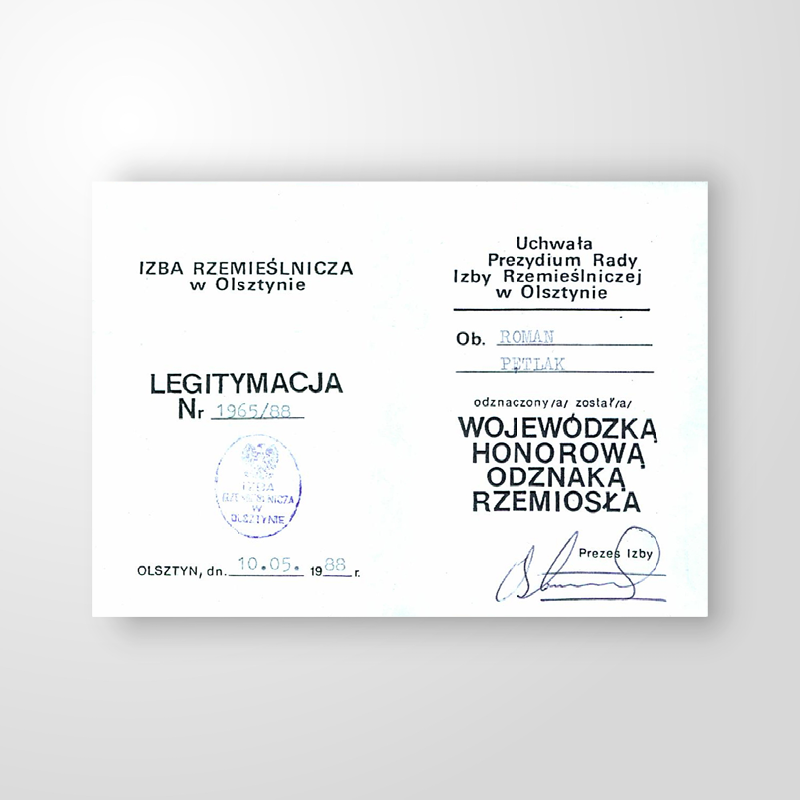

Roman fought for recognition, but also for people at work. Although working for a so-called privateer was not appreciated at that time, many trusted him and worked long years in ERKO.

Those were beautiful days for the sales department – a loaded to the roof pick-up truck would leave the works in Jonkowo monthly to supply all shipyards in Poland. This is how the large-scale production of cable lugs began. Today it counts over 2 500 typical dimensions and tools for electrotechnical works.

ERKO – FAMILY BUSINESS

Roman’s brothers, Józef and Jan, made the difficult and risky decision to leave their state jobs. They started the production of metal library racks in the family workshop. Joining the forces of the metal works and two single-entrepreneur locksmith’s workshops of Jan and Józef gave rise to the ERKO company.

TRADE FAIRS IN POLAND

“Let’s do good things for customers and don’t worry about money, because it will come by itself” – this was the Brothers motto, which gave the momentum to the newly established business. In a single year, the ERKO crew visited 26 trade fairs. They went on tour of all major cities in Poland in an old Volkswagen LT bus, which served as a demo car back then.

A HARD-WORKING VISIONARY

Out of the box thinking, innovative ideas, and drawing conclusions from past events, allowed Roman Pętlak to be always one step ahead of the competition. Not only in business. He was one of the pioneers in organising sailing cruises on Masurian lakes, and he often stood on the podium in the Omega sport class.

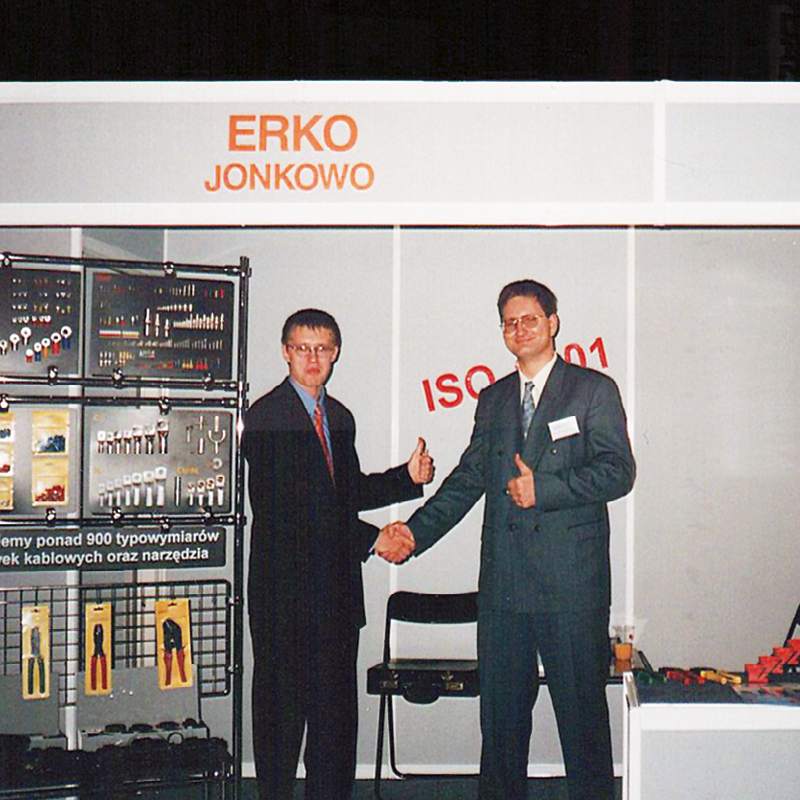

ISO 001/00

Earning the ISO 9001 Certificate in 1994 led to further development. ERKO was the first company in Poland to receive this quality certificate.

THE BEGINNING OF THE THIRD GENERATION

Roman’s son, Piotr Pętlak – the current CEO of ERKO, since young years spent his summer holidays working in his father’s company. After graduating from the Faculty of Electrical Engineering at the Gdańsk University of Technology in the field of Automation and Robotics, he joined Zakłady Metalowe ERKO.

He became a jack-of-all-trades there. He helped with computerisation of office work and created the first product catalogues. He participated in works on new products and dealt with supply and sales.

TAKING THE HELM

After the sudden death of Roman Pętlak in 2000, the company partners appointed his son, Piotr, to manage the company. The support of dedicated employees and the invaluable know-how deciphered from the personal notes of the late founder, made it possible for Piotr, who had only five years of experience in business, to manage the company.

The notes left by Roman served as a practical manual for managing the production company. They contained information on production technology, sales, marketing, procurement, and personnel management.

Piotr’s brother, Michał, who graduated from the Faculty of Law at the University of Warsaw, joined the management of the family business a year later.

THE GENE OF INNOVATION

Entrepreneurship turned out to be a trait passed down from generation to generation. Piotr and Michał, together with their business partners, Józef and Jan, worked on development of export and focused on automation of production processes. In 2003, they purchased the first CNC milling machine, which made it possible to improve the quality and increase the production capacity of parts for hydraulic presses.

A EUROPEAN PERSPECTIVE

The modern tool production hall in Jonkowo was built owing to acquisition of many European founds, including the pre-accession PHARE (Poland and Hungary: Assistance for the Restructuring of the Economy). In the following years, halls for the production of cable terminals were built. It was possible to expand the infrastructure and technology in the plant in Czeluśnica.

Owing to continuous investments in plants in Czeluśnica and Jonkowo, ERKO expanded its operations. In addition to ELECTRO division, which stems from the company roots, two new areas of activity were developed:

– the AERO division – specialising in production of parts for the aviation industry, and

– the ROBOTICS division – dealing with automation and robotisation of production processes.

CHANGE IS INEVITABLE

In 2009, ERKO co-founders Jan and Józef went into well-deserved retirement. Their sons, Maciej and Marcin, joined the management of the company. From that moment on, the next generation of the Pętlak family bacame responsible for the company’s development.

Thanks to cooperation with Family Business Institute in Poznań, as well as the increase in knowledge about the specificity of family businesses, the next generational game changers will be better prepared for management. Planned and skilfully led by the team of Dr Adrianna Lewandowska, Piotr’s sons, Adam and Wojciech, started supporting ERKO with their activities specific to the young generation.

ERKO 4.0

In 2020, the owners of ERKO signed contracts for financing and construction of a modern and technologically advanced factory in Jonkowo. It laid the foundations for construction the most innovative centre for the development of industrial automation and robotisation, a place of vocational education, and above all – a friendly workplace.

1938 CZELUŚNICA

A year before the beginning of World War II, Piotr Pętlak, father of ERKO founder Roman Pętlak, built a blacksmith’s and locksmith’s workshop in Czeluśnica. Back then it was a small wooden building. The front line stood right next to it. As a result of the war, the walls of the house were shelled and the forge was demolished.

THERE WHERE THE HORSES WERE BEEN SHED

During the times of the Polish People’s Republic, Piotr Pętlak bought a Lemko two-room smoke hut. After disassembly, it was transported to Czeluśnica, where it set up a forge which was comfortable for those times. Years later it turned out that history likes to surprise. In 2015, this is exactly where the first operation of cutting off the castings of blades for modern Pratt-Whitney Rzeszów passenger aircraft engines was performed.

THE FORGE OF CHARACTER

Roman Pętlak – Piotr’s eldest son – worked hard as a child, helping his parents in the fields, with farm animals and in the smithy. Additionally, he took care of five younger siblings. He studied very well and wanted to be a constructor. He got into the Technical School of Shipbuilding in Gdańsk (CONRADINUM), and then continued his studies at the Faculty of Mechanical Engineering at the Gdańsk University of Technology and at the Fisheries Study in Szczecin.

He was going through difficult times away from his family. Sometimes there wasn’t enough money for the basics. Even then, he promised himself that his family would never run out of anything.

COURSE ON WARMIA

For the love of a beautiful dentistry student at the Medical Academy, Roman Pętlak moved to Olsztyn. It was not an easy decision for an already successful builder involved in the construction of krill and fish vessels. Instead of building huge ships, he started calculating simple structures in a small local company. However, ambition and diligence drove him to continue.

As deputy and then technical director of OLPASZ, he designed an integrated feed production and storage system, which was awarded the NOT medal and disseminated throughout Poland. He traveled with the then Minister of Agriculture as an adviser to the USSR for negotiations with Georgia.

During martial law, Roman’s life turned upside down. For his active activity in the Solidarity movement, he was “fired” from work and received a wolf ticket from the authorities, without the possibility of employment in Olsztyn and its vicinity.

1981 JONKOWO

Fiat 125p, a summer house built together with brothers Jan and Józef and a modest collection of stamps inherited from his parents-in-law – this is a property that has become a contribution to a new activity. With the money raised, a small building was built in Jonkowo near Olsztyn, where the Roman Pętlak Metal Plant was established.

It began with the production of forks, hoes and small furnaces for heating. From his colleagues from the shipyard, Roman learned about the need for cable terminals, which the socialist state industry was unable to produce. He took up the challenge and despite initial problems with access to materials and gaining acceptance for capitalist artisanal production, Roman Pętlak’s products passed the tests and quality tests required by the maritime market.

BUSINESS WITH A VISION

Roman fought for recognition, but also for people to work. And although at that time, taking up a job “for a private worker” was not appreciated – many trusted him and he still works in ERKO.

Beautiful times have come for the sales department – once a month, a Żuk car, loaded to the roof, left the Jonkowo plant to supply all shipyards in Poland. This is how the large-scale production of cable lugs began, which today has more than 2,500 typical dimensions and tools for electrotechnical works.

ERKO – FAMILY BUSINESS

Roman’s brothers, Józef and Jan, made the difficult and risky decision to leave their state jobs. In the family factory, they started the production of metal rack structures for libraries. The combination of the forces of a metal factory and two one-man Zakłady Ślusarskie Jan and Józefa gave rise to the ERKO company.

FAIR POLAND

“Let’s do good things for customers and don’t worry about money, because it will come by itself” is the motto of the Brothers, which gave impetus to the newly established business. During the year, the ERKO crew visited 26 fairs in all major cities in Poland. The tournée took place, among other things, in an old Volkswagen LT bus, which served as a then unknown “demo car”.

A WORKING VISIONARY

Out of the box thinking, innovative ideas and drawing conclusions from past events, allowed Roman Pętlak to be one step ahead of the competition. Not only in business. He was one of the pioneers in the organization of sailing cruises on Masurian lakes, and in sports in the Omega class he often stood on the podium.

ISO 001/00

The passport to further development was obtaining the ISO 9001 Certificate. In 1994 ERKO became the owner of the first document in Poland which was responsible for ensuring quality.

THE BEGINNING OF THE THIRD GENERATION

Roman’s son, Piotr Pętlak – the current CEO of ERKO – spent his summer holidays working in his father’s company. After graduating from the Faculty of Electrical Engineering at the Gdańsk University of Technology in the field of Automation and Robotics, he joined Zakłady Metalowe ERKO.

He was then a man of everything. He helped with computerization of office work, created the first product catalogs, participated in the work on the new assortment, and dealt with supply and sales.

TAKE REINS

After the sudden death of Roman Pętlak in 2000, ERKO management was taken over by his son – Piotr, chosen by the partners. Thanks to the support of dedicated employees and the invaluable know-how recorded in personal notes by Roman, it was possible to manage the company by Piotr, who had only five years of experience in it.

The notes left by Roman served as a practical manual for managing a production company. They contained information on production technology, sales, marketing, procurement and people management.

After a year, Piotr’s brother, Michał, who graduated from the Faculty of Law at the University of Warsaw, joined the management of the family business.

GEN OF INNOVATION

Entrepreneurship turned out to be a trait passed down from generation to generation. Piotr and Michał, together with their partners – Józef and Jan, became involved in the development of exports and focused on the automation of production processes. In 2003, they purchased the first CNC milling machine, which made it possible to improve the quality and increase the production capacity of parts for hydraulic presses.

A EUROPEAN PERSPECTIVE

Thanks to the acquired many European funds, including the pre-accession Phare (Poland and Hungary: Action for the Restructuring of the Economy), a modern tool production hall was built in Jonkowo. In the following years, halls for the production of cable terminals, and it was possible to expand the infrastructure and technology in the plant in Czeluśnica.

Thanks to continuous investments in plants in Czeluśnica and Jonkowo, ERKO expanded its areas of activity. In addition to the ELECTRO division, from which he comes, the AERO division has developed – specializing in the production of parts for the aviation industry, and the ROBOTICS division – dealing with the automation and robotization of production processes.

THE ONLY WHAT IS PERMANENT – CHANGES

In 2009, ERKO co-founders Jan and Józef went into well-deserved retirement. Their sons, Maciej and Marcin, joined the management of the company. From that moment on, the next generation of the Pętlak family was responsible for the company’s development.

Thanks to the cooperation with the Family Business Institute in Poznań, as well as the increase in knowledge about the specificity of family businesses, the next generation change will be better prepared for management. Planned and skilfully led by the team of Dr. Adrianna Lewandowska, Adam and Wojciech – Piotr’s sons, started supporting ERKO with their activities specific to the young generation.

ERKO 4.0

In 2020, the owners of ERKO signed contracts for financing and construction of a modern factory in Jonkowo. This is how the construction of a technologically advanced factory in the region began, an innovative center for the development of industrial automation and robotization, and vocational education, but above all – a friendly workplace.