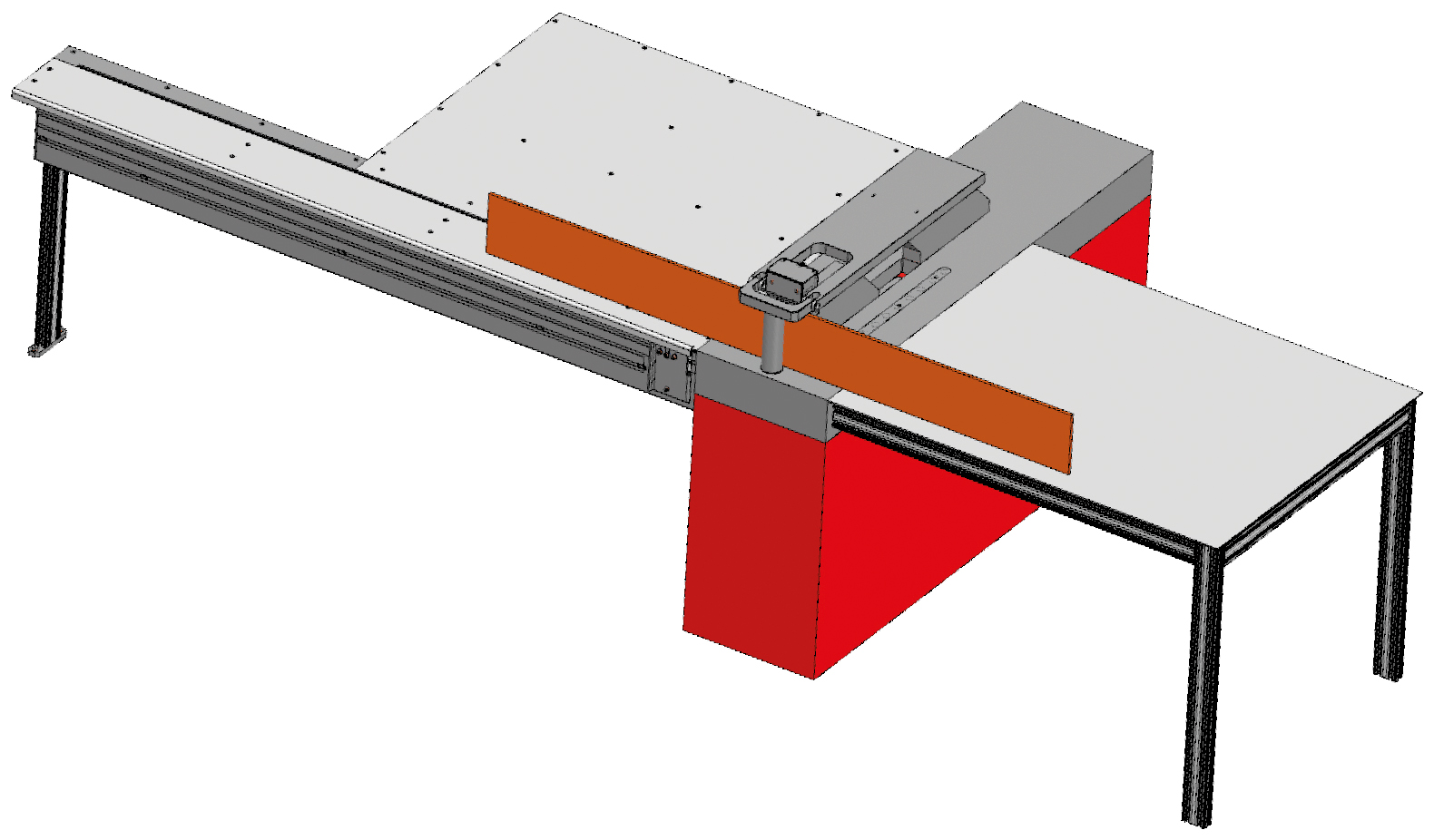

SH900PLC busbar processing station

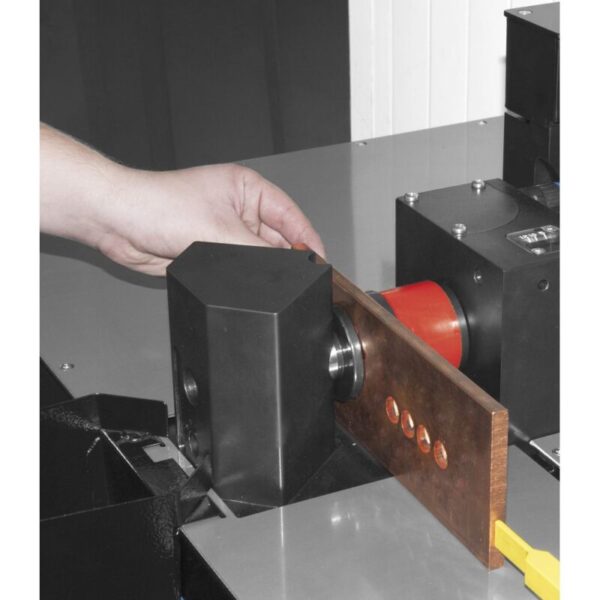

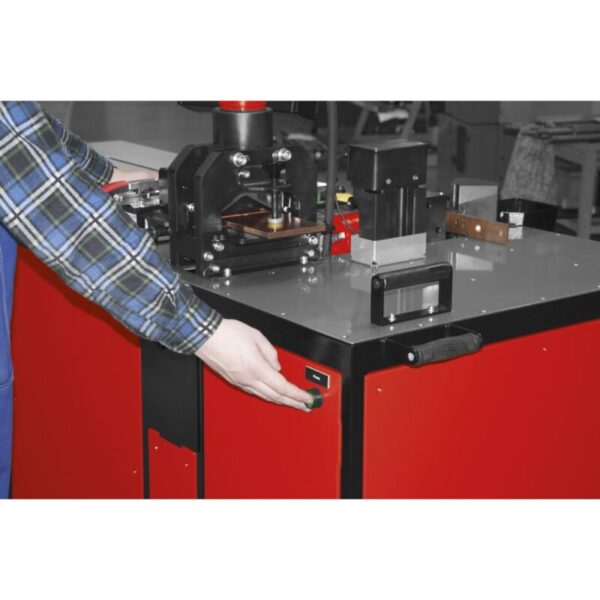

Station for Al and Cu busbars precise cutting, bending, hole punching, inserting nuts, offsetting:

• busbar width from 30 ÷ 125 mm

• busbar thickness 5 ÷ 12 mm

• bending angle range up to 90°

Special features:

• equipped with LED touch screen programmed in: Polish, Russian, English, German and Czech (other languages on request)

• equipped with electronic, programmable bending angle sensor (setting precision 0,5°)

• equipped with measuring rulers enabling precise positioning of 0,1mm

• precise height adjustment of hole punching head (0,2mm precision)

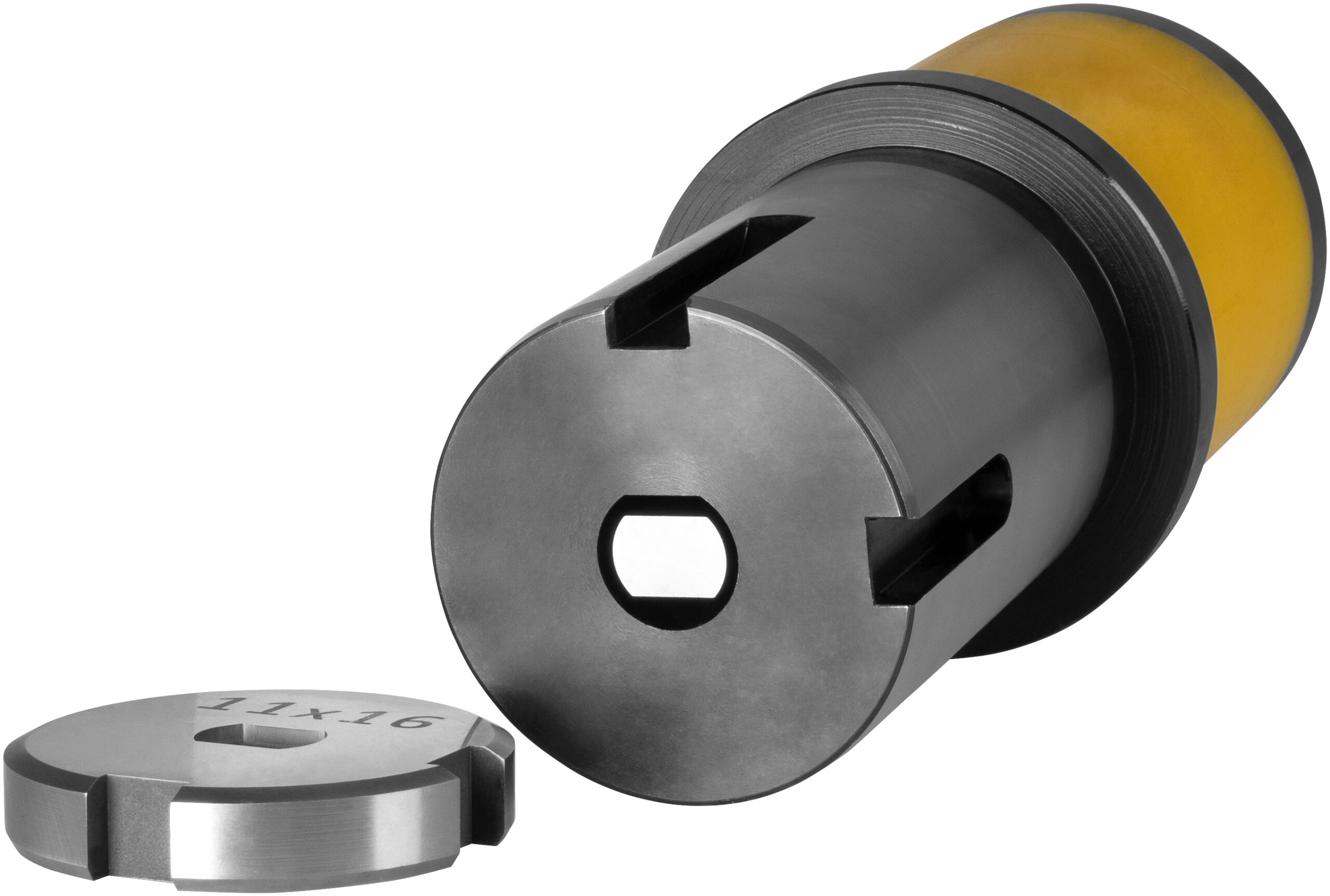

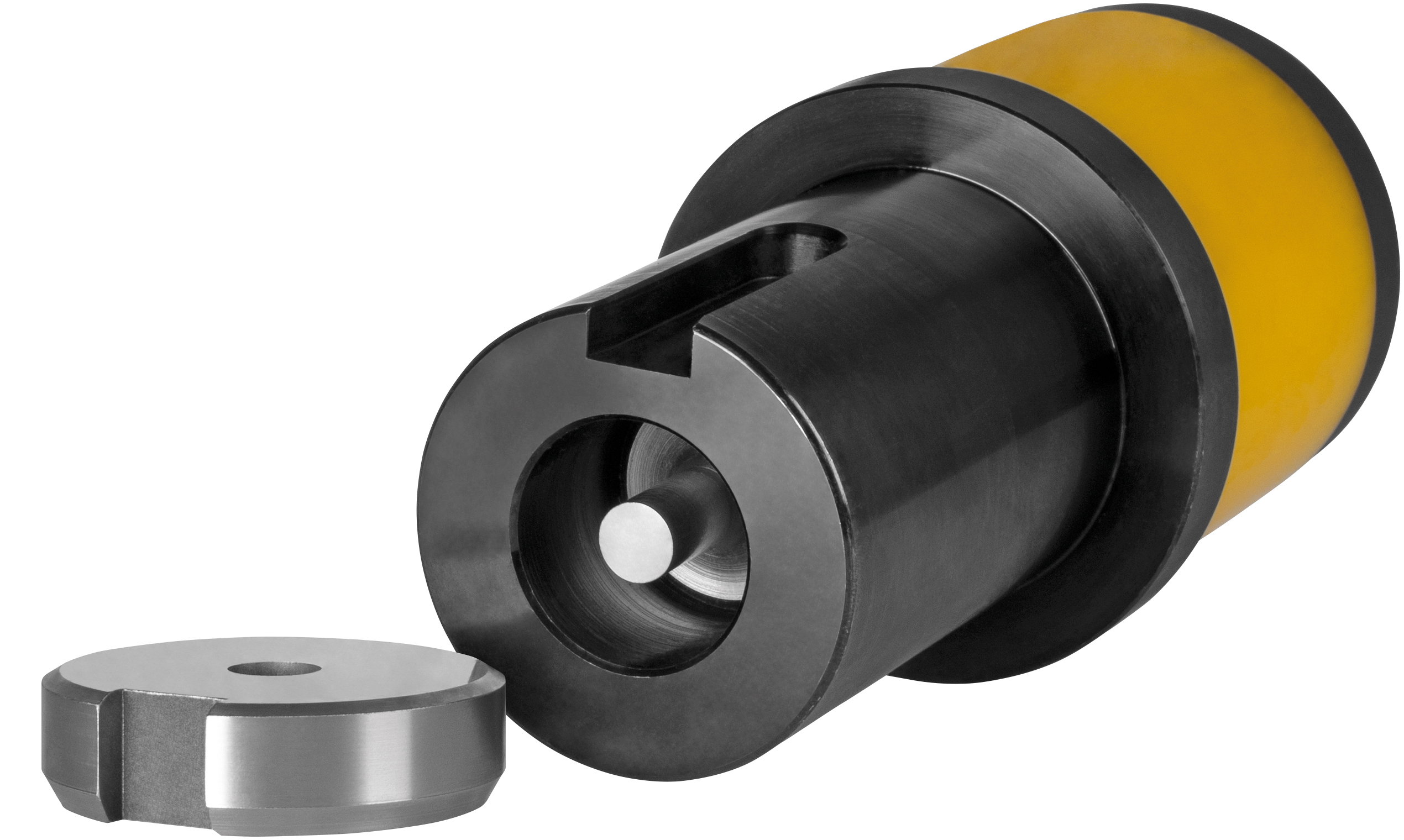

• burr-free round and oval holes punching

• burr-free busbars cutting

• built-in reliable hydraulic drive

• automatic identification of inserted dies

• bending angle correction complying busbar flexibility

• electronic length measurement of cut busbar (up to 6m)

• electronic length measurement of bent and punched busbar (up to 0,5 or 1,2m)

• busbar offsetting repeatability

• additional worktop

• tilt, rotatable touch screen

• equipped with control socket

• equipped with port for ERKO hydraulic heads (hydraulic hose with quick coupler PM 630 bar)

• standard set for inserting nuts include SH 407 insert and round hole punch SH 403 (need to be ordered separately)

Total dimensions: (LxWxH): 1400 x 930 x 1420 mm;

Weight incl. standard equipment: 355 kg; Pressure: 630 bar;

Power: 3 x 400V/230V; 1,4 kW or 1 x 230V

- VIDEO

- TECHNICAL DATA

- LED PANEL

| Equipment | Type | SH 800PLC-Gold | SH 800PLC-Platinum |

| Insert for precise bending (built-in encoder) | SH 401PLC-E | √ | √ |

| Busbar cutter | SH 405 | √ | √ |

| Length sensor for cut busbar | SH 415PLC | x | √ |

| Insert die for busbars offsetting | SH 406PLC | √ | √ |

| Additional worktop | SH 408PLC | x | √ |

| Extended measurement of length L (range from 0 to 1020 mm) | SH 418PLC | x | √ |

| Round hole punch (standard dimensions according to catalog) | SH 403 | x | x |

| Oval hole punch (standard dimensions according to catalog) | SH 404 | x | x |

| Rectangular hole punch (dimensions according to order: max diagonal 21 mm, side not shorter than 6,6 mm) | SH 409 | x | x |

| Insert die for inserting nuts | SH 407 | x | x |

| Additional busbar support | SH 408 | x | x |

| Bending with correction (complying busbar flexibility) precision of bending ±0,5° | √ | √ | |

| Measurement of height H, precision 0,2 mm | √ | √ | |

| Measurement of lenght L, range 0-500 mm, precision 0,1 mm | √ |

√ – standard equipment,

x – additional equipment on request

The panel includes a graphic instruction manual: