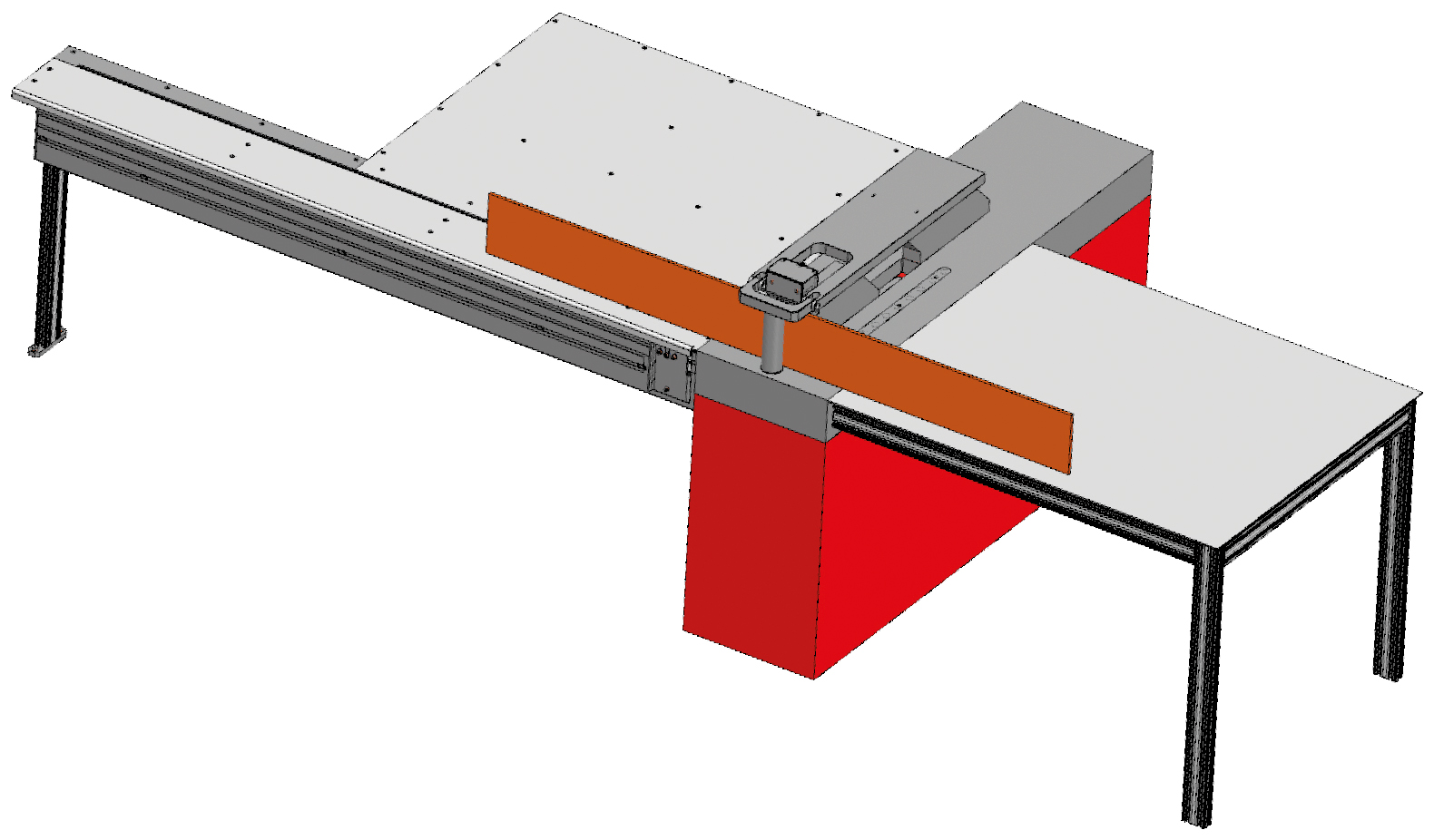

HG 200 Busbar bending station

Station for precise Al and Cu busbar bending:

• width range of cut busbar 50 ÷ 180 mm

• width range of bent busbar 50 ÷ 200 mm

• thickness range of bent and cut busbar 5 ÷ 15 mm

• bending angle range up to 90°

Special features:

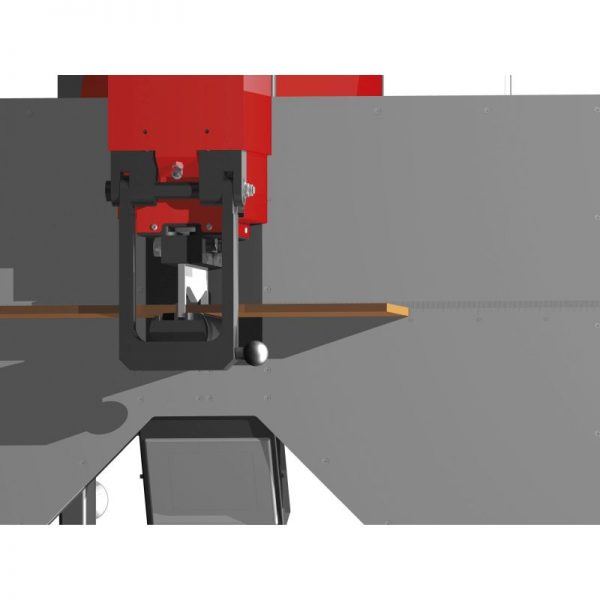

• equipped with angle compensation system, consequent to flexibility of bent material

– standard radius of bending inserts: R5; R8; R10; R12; R15; R20

(other sizes on request after technical consultation)

– 4 bending inserts can be used with station (3 standard of which 1 included in the price,

others paid extra, and 1 non standard custom maid)

• easy in operation panel, minimizing time for programming

• ergonomic worktop shape assuring precise bending of long busbars

• stable construction and low weight same time

• efficient, compact electric hydraulic unit, with low electricity consumption makes

the device very economical

• possibility of adjusting the station for individual customers needs

Total dimensions (LxWxH): 1200 x 1230 x 1274 mm;

Weight with standard equipment: 450 kg;

Force 30 kN at a pressure of 400 bar;

Power supply: 3 x 400V / 230V; 1,68 kW

- VIDEO

- HG 200 stand equipment

For the station below inserts are available:

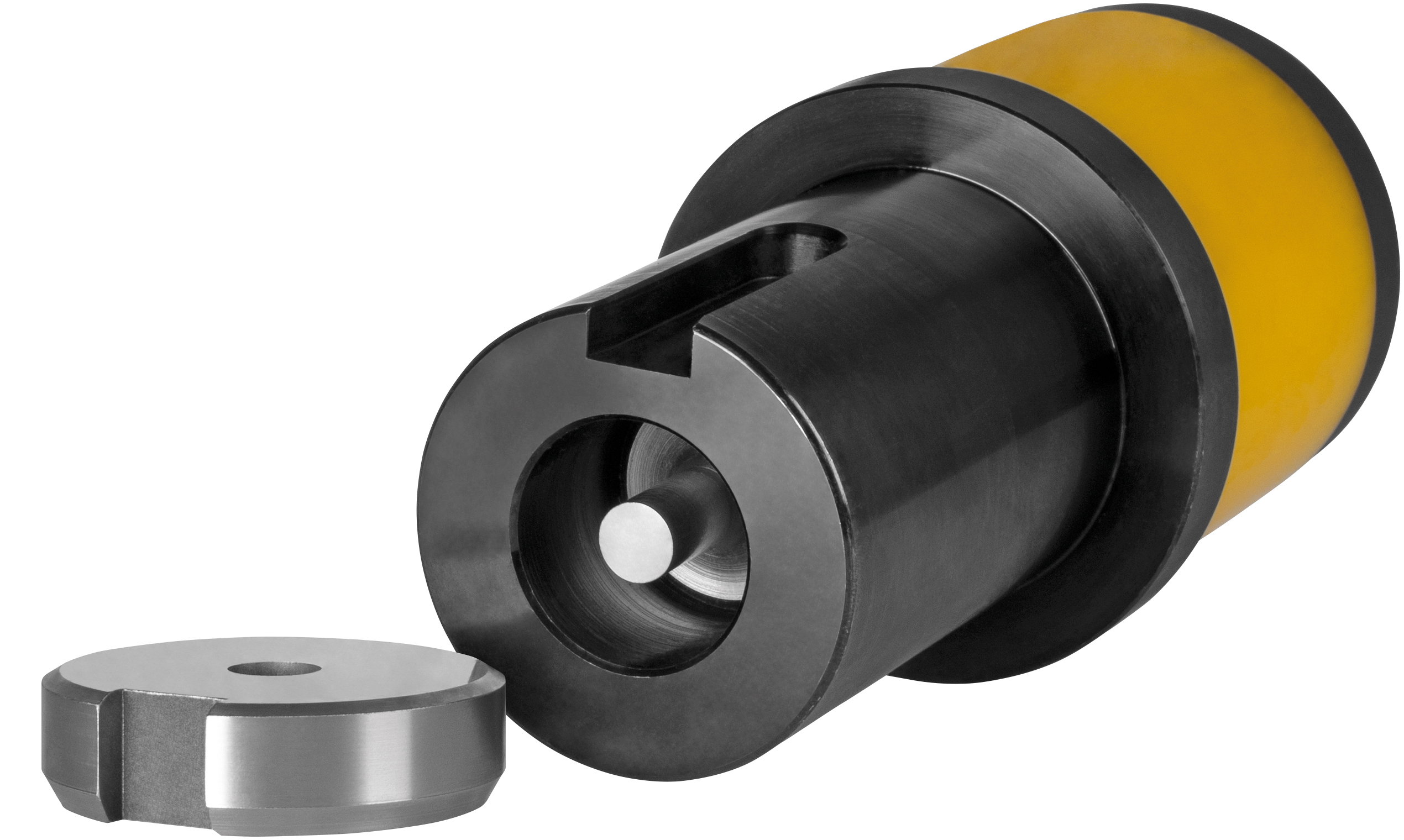

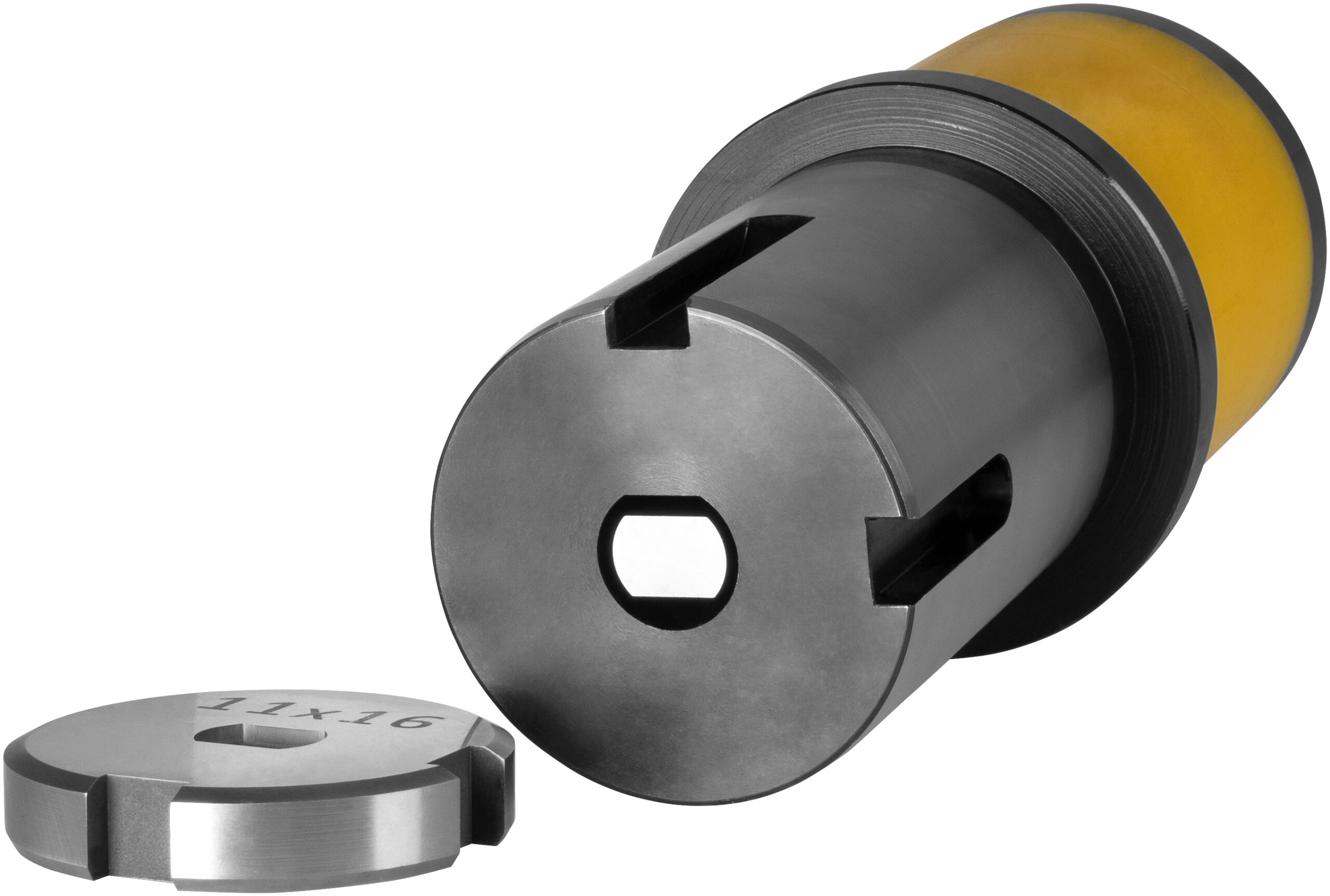

• cutting insert HG 205

• 3 standard bending inserts HG 201:

HG 201-G20 insert allows bending busbars of range:

HG 201-G20 insert allows bending busbars of range:

Thickness: 15 ÷ 20 mm

Busbar width: 50 ÷ 150 mm

HG 201-G15 insert allows bending busbars of range:

HG 201-G15 insert allows bending busbars of range:

Thickness: 8 ÷ 15 mm

Busbar width: 50 ÷ 200 mm

HG 201-G8 insert allows bending busbars of range:

HG 201-G8 insert allows bending busbars of range:

Thickness: 5 ÷ 8 mm

Busbar width: 50 ÷ 200 mm

NOTE: use bending stamp with radius equal to busbar thickness.

| Insert | A | B | C | L for C=95 mm | L for C=105 mm |

| HG 201-G20 | 65 | 65 | 80 | 95 | 500 |

| HG 202-G15 | 45 | 45 | 75 | 95 | 500 |

| HG 203-G8 | 40 | 40 | 75 | 95 | 500 |

Other inserts on request after technical consultation.