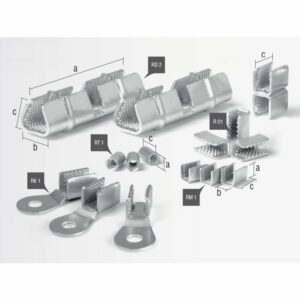

SHARK connectors for Al wires

SHARK technology is dedicated to connect winding enameled wires in motors and oil transformers, copper and aluminum wires, round and rectangular wires. We provide technical advice by recommending Shark connections and other configurations according to arrangements with customer.

- Description

- TECHNICAL DATA

Description

• Quality of connection: Connections made with Shark connectors conform with the requirements of PN-EN 61238 -1 standard, and have been awarded a certificate

issued by Electrotechnical Institute from Warsaw

• Durable connection: Connections made with Shark connectors have been in use in transformers for over 10 years. In the process of cable isolation, the bale narrows (notch is formed), which leads to a local reduction in cross-section and mechanical weakening of the cable. Using SHARK technology products eliminates this problem, which leads to longer indefectible use of cables and devices, in which connectors and terminals are installed.

• Clean technology: Thank to use of Shark technology, process of removing enamel insulation from the wires has been eliminated. When connecting wires there is no need to secure the transformer against generated impurities. The ecological and environmental aspects are extremly important. Using Shark terminals and connectors eliminates dangerous waste. Process of connecting wires with insulation or enamels requires using mechanical or chemical methods. Mechanical methods include insulation scrapping which can cause dust and pollution of the working environment. Another method is heathing or soldering insulation using hard solder with addition of silver. It causes pollution of environment by toxic results of this process and also requires service staff to have special permissions. Chemical method consists in dissolving insulation in corrosive substances. Both methods have many technological and environmental disadvantages. Shark technology eliminates all those problems. Thanks to this, there is no dusting of the working environment, permeation into the environment dangerous waste such as enamel and native material. There is also no pollution that is dangerous for the process and further operation of the transformer from the cleaning process. The risk of short circuits during the further operation of the transformer is reduced, which turns info increased indefectible work of the entire network.

• Environment friendly technology: Shark connector fast and reliably replaces harmful to the environment soldering and enamel insulation burning processes.

• Easy operation: Dedicated and efficient tools and ERKO team help in preparing technology, enable trouble free implementation of Shark technology at customer’s plant.

• Increased efficiency: All our customers who implemented Shark technology gained a significant increase in performance comparing to previously used technology.

• Economical technology: Elimination of preparatory processes, energy consuming soldering process, reduction of stored connectors range, high efficiency of he process makes Shark technology more beneficial than traditional methods. Traditional method of connecting wires requires from operators precise, complicated technology and using tools dedicated to the given wire cross-section (e.g. in case of crimping filled wires). Making connectios using Shark connectors and terminals guarantee repeatability and effectiveness of the connection. ERKO also offers dedicated and efficient tools enablingsmooth implementation of Shark technology in enterprises.

• Universal technology: With one Shark connector can make connection using wires of different cross-section, shape and material. Having over a dozen of connectors, any wire within scope of Shark connectors can be connected. We are able to recommend alternative cnnection solution of any presently used by customer. Enamelled insulated copper or aluminum wires can be connected. Connectors can be used for connecting profile and round wires. Shark connectors can be also used (with observance of the erelvant rules) for connectins single-strand wires without insulation and multi-strand wires withoud insulation. After making connection with terminals and connectors, connector’s teeth bithe through the insulation and stick into the core of the connected wire. This way we receive electrical and mechanical permanent connection.

|

Recommended for Al wires |

|||||||||||

|

Connector type |

Round wires Diameters range [mm] |

Rectangular wires range [mm] |

Total cross section [mm2] |

Connector’s dimensions [mm] |

Crimping tool |

||||||

|

Thicknes |

Width |

||||||||||

|

Ømin |

Ømax |

min |

max |

min |

max |

a |

b |

c |

|||

|

RT 1 |

0,8 |

1,9 |

|

|

|

|

1,77 |

Ø7 |

– |

11 |

GRT 1, EGRT 1 |

|

RT 2 |

0,8 |

1,9 |

|

|

|

|

3,54 |

Ø7 |

– |

22 |

|

|

RM 1 |

0,8 |

2,2 |

– |

– |

– |

– |

3,5 |

8 |

8 |

12,5 |

GRM 1, EGRM 1 |

|

RM 2 |

0,8 |

2,2 |

– |

– |

– |

– |

3,5×2 |

8 |

8 |

28 |

|

|

R 01 |

1,5 |

3 |

2 |

4,5 |

2 |

2,3 |

10,5 |

10,5 |

10 |

19,5 |

GR 1 |

|

R 1 |

1,5 |

5 |

2 |

4,1 |

2 |

7,1 |

26,6 |

14,5 |

13 |

19,5 |

|

|

R 1S |

1,5 |

5 |

2 |

4,1 |

2 |

7,1 |

26,6×2 |

14,5 |

13 |

42 |

|

|

R 2 |

1,5 |

5 |

2 |

4,1 |

2 |

7,1 |

26,6×2 |

29 |

13 |

19,5 |

|

|

RK 1** |

1,5 |

4 |

2 |

4,1 |

2 |

7,1 |

26,6 |

14,5 |

13 |

49 |

|

|

RDO 1 |

|

|

3,15 |

4 |

5 |

14,5 |

25-65 |

19 |

23,5 |

65,5 |

GRD 1 |

|

RD 1 |

|

|

3,15 |

4 |

5 |

14,5 |

25-65 |

19 |

23,5 |

36,5 |

|

|

RD 2 |

|

|

3,15 |

6,5 |

5 |

14,5 |

25-65×2 |

19 |

23,5 |

81,5 |

|

** hole for M8, M10, M12 screw