RNT Heat shrinkable repair sleeves

Heat shrinkable repair sleeves for quick, durable and efficient repair of the

damaged cable coating without the need to cut it and for the purpose to protect the

mechanical, corrosion and water supply and gas pipelines.

• covering the inner surface of the sleeve with a layer of hot melt glue, guarantees

accurate and resistant to external conditions bonding with cable coat and

compensation for any unevenness

• coating the outer layer of the sleeve with thermochromic paint which changes

color after reaching the target temperature and prevents overheating of the material

during its shrinking

- TECHNICAL DATA

|

Symbol |

Colour |

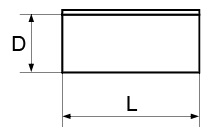

D max. Ø |

D min. Ø |

Wall thickness before shrinking together |

Lenght L [mm] |

|

RNT 42-08-250/1 |

black |

42 |

8 |

0,9 |

250 |

|

RNT 42-08-500/1 |

black |

500 |

|||

|

RNT 42-08-750/1 |

black |

750 |

|||

|

RNT 42-08-1000/1 |

black |

1000 |

|||

|

RNT 42-08-1500/1 |

black |

1500 |

|||

|

RNT 76-22-250/1 |

black |

76 |

22 |

0,9 |

250 |

|

RNT 76-22-500/1 |

black |

500 |

|||

|

RNT 76-22-750/1 |

black |

750 |

|||

|

RNT 76-22-1000/1 |

black |

1000 |

|||

|

RNT 76-22-1500/1 |

black |

1500 |

|||

|

RNT 100-30-250/1 |

black |

100 |

30 |

0,9 |

250 |

|

RNT 100-30-500/1 |

black |

500 |

|||

|

RNT 100-30-750/1 |

black |

750 |

|||

|

RNT 100-30-1000/1 |

black |

1000 |

|||

|

RNT 100-30-1500/1 |

black |

1500 |

|||

|

RNT 139-38-250/1 |

black |

139 |

38 |

0,9 |

250 |

|

RNT 139-38-500/1 |

black |

500 |

|||

|

RNT 139-38-750/1 |

black |

750 |

|||

|

RNT 139-38-1000/1 |

black |

1000 |

|||

|

RNT 139-38-1500/1 |

black |

1500 |

|||

|

RNT 185-55-250/1 |

black |

185 |

55 |

0,9 |

250 |

|

RNT 185-55-500/1 |

black |

500 |

|||

|

RNT 185-55-750/1 |

black |

750 |

|||

|

RNT 185-55-1000/1 |

black |

1000 |

|||

|

RNT 185-55-1500/1 |

black |

1500 |

|||

|

RNT 210-55-250/1 |

black |

210 |

55 |

0,9 |

250 |

|

RNT 210-55-500/1 |

black |

500 |

|||

|

RNT 210-55-750/1 |

black |

750 |

|||

|

RNT 210-55-1000/1 |

black |

1000 |

|||

|

RNT 210-55-1500/1 |

black |

1500 |

|

Characteristics |

||

|

Physical |

Tensile strength Elongation at break Moisture absorption Resistance to radiation ESCR 48 hours at 50°C |

17,5 N/mm2 (min) 300% (min) 0,1% (max) lack of dissection lack of cracks |

|

Physical |

Tensile strength Elongation at break |

15 N/mm2 (min) 200% |

|

Electrical |

Dielectric strength |

12 kV/mm(min) |

|

Chemical |

Chemical resistance Tensile strength Elongation at break |

good 15 N/mm2 (min) 200% |

|

Limit |

150°C during 30 min 250°C |

lack of colour change |