As one of the key suppliers of the electrotechnical industry, ERKO stands out with great care for the highest quality of its products. To ensure the competitiveness of the products, ERKO constantly creates its own, innovative technological and constructional solutions. In response to the constantly growing needs of the modern market, the ERKO R&D team has developed a new generation of PIRANIA screw connectors and terminals.

Screw connectors and terminals are used to connect copper and aluminium power transmission cables of medium and low voltage class 1, 2 and class 5. They are indispensable on the construction site and during modernization or repair of electrical and power networks, including offshore and onshore wind farms powered under harsh conditions.

Screw connectors and terminals are more convenient to use than the connectors in crimping technology, therefore they are more and more popular among installers. Screw connectors are a perfect alternative to crimping technology, as they have numerous advantages, which include among others universality, high quality of connection and possibility of quick and easy installation.

PIRANIA screw connectors’ and terminals’ functionality

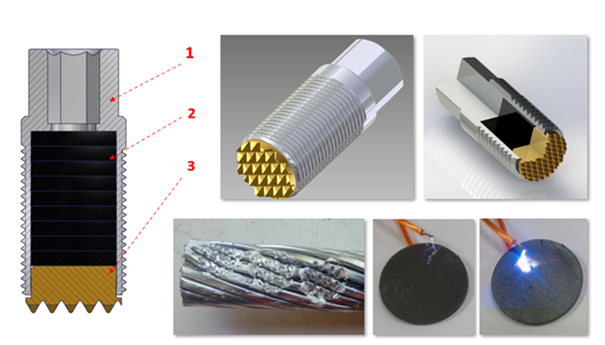

ERKO has developed and patented a new generation of screw connectors and terminals called PIRANIA. The system stands out with a special design of the cable core pressing unit to the body of connector and terminal. The idea behind the innovative technology is that after tightening the screw to the cable core, the screw breaks off at the thread root – always flush with the body regardless of the type of the core. This is possible due to the use of a cone-shaped tubular bolt and self-generated axial forces stretching the bolt in the section between the connector body and the bolt head. The connector’s body thread has the appropriate length, thanks to which the screw after breaking is always flush with it’s external surface.

PIRANIA technology innovation

The PIRANIA system is innovative on a global scale. The unique features of the system include: invariable repeatability of the screw breaking place, thanks to the special design of the pressing unit. Regardless of the type and size of the conductor, in the PIRANIA system the screw always flush with the outer surface of the connector body. The indisputable advantage of the system is, above all, its universality, which allows for a significant reduction in the number of required sets of connectors and pressing units compared to traditional solutions. It is possible to use a single connector for wires of various conductor structures and cross-sections.

The innovative system guarantees no damage to the cable core during the connector installation process due to the use of a non-rotating screw tip with a special shape, dedicated to the construction of the conductor. The special shape of the screw tip also ensures higher resistance to the relaxation of pressure forces. The implementation of semi-conductive discs, that fill the axial opening of the screw, has significantly reduced partial discharges in the connected wires. Connections made with the PIRANIA system are repeatable in terms of the required clamping force due to the use of non-rotating screw tip.

Undoubtedly, a special feature of PIRANIA technology is the possibility of connecting class 5 flexible conductors, for which there are currently no screw connectors guaranteeing permanent connections.

An alternative for crimping technology

Screw terminals and connectors are simple in use and easy to install, especially in hard-to-reach places. To mount the screw connections, the installer only needs an Allen wrench, a socket or a universal holder to hold the screw and terminal in place.

Currently, there are many types of screw terminals and connectors available on the market, that do not differ much in bodies, but have completely different types of screws and threads. Popular screws are often made of brass or aluminium (with or without tin plating). The control of the breaking torque and breakage height of the screw is in this case defined by circumferential grooves installed on the core of the screw. The grading means that each subsequent groove towards the screw head has a higher breakage moment. This solution is unfavourable, as the largest of the cross-sections that can be used in a given type of connector or terminal is pressed down with a smaller force than the conductor with the smallest cross-section, which is deformed and relaxed by greater pressure. In some solutions, it is possible to tighten down a badly broken screw, which, however, results in a negative impact on the quality of the connection. If there is no possibility of tightening the screw, it is necessary to file it down, which is dangerous due to the possibility of contamination of the connection with filings that can pierce the coupling.

It is very important to ensure a long-term and stable connection, as the screw connectors must last from 25 to even 50 years. Since the screw is in direct contact with the conductor, there are time-varying effects that lead to chemical or mechanical damage of the conductor’s surfaces. The shear screw, in turn, is designed to create the largest possible effective contact surface between the two metal contact elements – between the body of the connector or terminal and the service wire. Thanks to the plastic deformation of these elements, the existing foreign layers, such as the oxide layer, are destroyed. It is worth paying attention to the regularity: the more contact surfaces, the lower the contact resistance.

The advantages of shear off screw technology

- The possibility of using one connector for conductors that differ in structure and within wide cross-section range

- Savings in terms of keeping smaller stock level (e.g. 2 types of connectors will be enough instead of 10)

- Versatility

- Rapid assembly

- Wide cross-section range

- Simple and quick assembly (with the use of small and lightweight tools)

How was PIRANIA created?

The ERKO R&D team has worked on the creation of the PIRANIA system for three years and the work was divided into three stages.

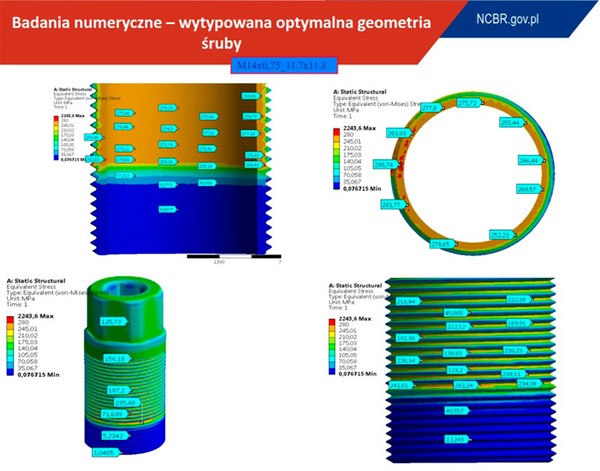

In the first stage, designs of all elements of the connection system were developed. In the full designed range, they were transferred to the 3D environment (Autodesk Inventor), where they were also optimized for numerical analysis and then imported to the calculation program. Simulations covering both elastic (ANSYS) and elastic-plastic (Deform 2D/3D) deformations of individual numerical models were performed. That allowed for a comprehensive analysis of the capacity ratio of each of the system components and, at the same time, for mapping of the deformation of the cable cores during the actual connection process. These works were carried out by the Design Team from the AGH University of Science and Technology in Krakow.

Three entities participated in the second stage of the research:

- ERKO responsible for heating the connection systems of the created prototypes in the current cycles; for measurement of the transition resistance of connection systems and for testing the strength properties of the threads.

- AGH dealing with the evaluation of the new system in terms of mechanical properties, internal and surface quality and rheological resistance.

- IEN evaluating the new system in terms of electrical properties of the cable connection system according to PN-EN 61238-1:2004.

In the third stage of work, tests of final properties were carried out. They were performed mainly in the ERKO laboratory on the specialized measuring equipment adapted specifically for this purpose. Selected production batches were tested under condition of subcontract at AGH and IEN. These institutions conducted additionally technological supervision and experimentally verified the final manufacturing technology of a new cable connection system in real-life conditions.

Thanks to the mentioned stages of work and research, a range of PIRANIA connectors and terminals – globally innovative connection system for class 1, 2 and 5 cable conductors – was created.

Our connectors and terminals are certified by the Institute of Power Engineering in Warsaw and comply with the following standards:

- ZSNP connectors with 1kV IEC 61238-1-1:2018 (ed. 1.0) class A1, PN-EN 61238-1:2004

- KSNP connectors with 6 kV PN-EN IEC 61238-1-3: 2020-1 class A, IEC 61238-1-1:2018 (ed. 1.0) class A1

- ZSSP connectors with 36 kV, PN-EN IEC 61238-1-3: 2020-1 class A1, IEC 61238-1-1:2018 (ed. 1.0) class A1

- KSSP terminals with 36 kV PN-EN IEC 61238-1-3: 2020-1 class A1, IEC 61238-1-1:2018 (ed. 1.0) class A1

More about the innovative PIRANIA connection system: