Flexible busbar processing requires professional equipment that has an impact on ergonomics and ensure the satisfaction of tasks being completed. For this kind of work it is extremely important the precision and accuracy.

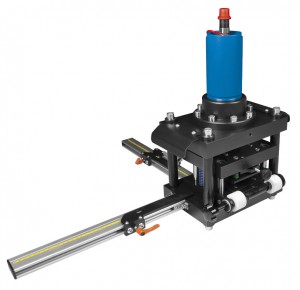

Responding to the customer demands, ERKO company offers flexible busbar processing stations HSE 100. This multifunctional device is designed for punching, cutting and stripping flexible busbars. It is possible to cut round holes with diameters from 6.6 to 21 mm. Maximum dimensions of processed rails are: 10 x 100 mm. The features distinguishing the device on the market is a very simple system for exchanging punches and dies, and easy replacement process for cutting and stripping dies.

Busbar processing becomes a seamless, thanks to detailed solutions used in the device. Flexible busbar processing stations HSE 100, gives precise accuracy in making cuts, with pre-installed measurement and centering module. The product works with a hydraulic pump H 800 or units AH 500 and AH 550, ERKO production. The device produces a pressure of 190 kN at an operating pressure of 630 bar. This model dimensions 490 x 390 x 490 mm. Total weight is 32.5 kg. Element for cutting the insulation HSE105 is ordered on Clients request. Read more about busbar processing stations.

|

Busbar processing in E-catalog. |