Electrical connector is also called a cable element of the electrical equipment that is used to connect the ends of the cable. The two ends without insulation should be placed in a groove fittings and crimped together.

How to crimp electrical connector?

Pressing an electrical connector on the cable can be very easy or difficult depending on what device you will use. Crimping is the process by which the construction tightens the fitting on the cable on one and the other side, joining them together permanently and securely.

Stages of crimping cable connectors:

Ist stage – select the correct connector according to the type, section and material of the cable. IInd stage – adjust the proper form of pressing, for example: trapeze, square, single indentation. All crimping forms can be found in Fig. 1.

Table no. 1 Source: http://erko-electro.com/offer/catalog/

IIIrd stage – once you select the appropriate crimping form for the cable connector it is time for pulling off insulation of the wire. Insulation must be pulled off on the same length as the coupling throat.

IVth stage – clean the wire from the oxides or corrosive air raids. Vth stage – place the wire in the throat of cable connector. VIsth stage – select appropriate crimper and crimping die. VIIth stage – tighten the connector on the cable up to the point when crimping dies come together with each other.

How the electrical connectors are labeled?

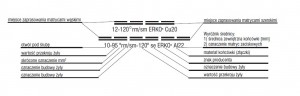

Knowing ERKO marking, you are able to read information such as, eg. the place of crimping, the material from which it is made, the diameter it has. Designation of the connectors are showed on Fig. 2.

Markingof the crimping for the tubular copper and aluminum connectors

Fig. 2. Marking of the crimping for the tubular copper and aluminum connectors

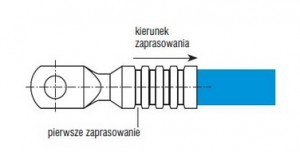

Crimping direction for the electrical connector

While crimping tubular copper and aluminum connectors you should note to remember to keep the right direction of crimping. One wire should be crimped on the right and the second left side. The correct way of crimping cable connector is presented in fig. 3.

Fig. 3. Crimping direction for the electrical connector

Source: http://erko-electro.com/offer/download/technical-data/

ERKO has a lot of different types of connectors in its range. All products are made with the top care and allow safe and durable connection of the two ends of the cable. Cable connectors can be classified depending on the material they are made of, ex. Cu, Al and Al – Cu, the size, the shape, ex. reduction, on whether or not the having insulation. Cable connectors are divided into basic categories:

- – Cu tubular terminals and connectors,

- – Al terminals and connectors,

- – Al – Cu terminals and connectors,

- – Shear off screw terminals and connectors 1 – 36 kV,

- – Medium voltage terminals and connectors,

- – Special terminals and connectors.

Learn more about electrician tools that you can use, inter alia, for crimping electrical connectors.

|

Electrical connector in E-catalog. |