Busbar processing includes cutting, bending, hole punching, offsetting as well as inserting nuts. All these works can be performed with the help of both single and multifunction devices for the busbar processing.

Flexible busbar processing

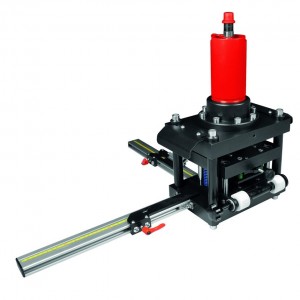

In the ERKO offer you can find HSE 100 a processing station for flexible busbars. This station is for hole punching, cutting and initial stripping of flexible busbars. You can process the busbar with the thickness from 4 to 10 mm and a width from 30 to 100 mm. The round holes cut in the busbar may have the diameter from 6,6 mm to 21 mm. The work with this equipment is fairly comfortable thanks to an easy system of exchanging stamps and dies. It is also very easy to exchange the insert for stripping . The accuracy of cutting is very high because the manufacturer installed rulers and a centering module. HSE 100 is compatible with hydraulic units produced by ERKO, e.g. pump H 800 or aggregate AH 500.

Mounting rail processing

Mounting rails processing is limited to cutting and punching holes. The cutters can be manual or hydraulic. The manual tools include GLS with the force of 45 kN. You can order any profile from those offered by the manufacturer. An example of a hydraulic cutter is GLP. The force of this tool is 80 kN with the weight of 3,4 kg. It works with hydraulic units produced by ERKO. Both tools are available with one or two profiles. A more complex tool, which can be used both for cutting rails and punching elliptical holes, is GLR 6.

Busbar processing

The group of tools and stations for busbar processing is very wide, it includes : benders, cutters and busbar processing stations. Punching holes is possible with a bender-puncher HGD125, which can be also used for bending busbars. You can process the busbar with the width from 30 -125 mm and the thickness from 5-10 mm. The holes punched in the busbar can be round with the diameter from 6,6 to 21 mm or oval with the diameter from 8,5 – 21 mm. The bender-puncher is equipped with rulers for positioning when punching holes. The force of this tool is 190 kN. The busbar cutter HC 125 is designed for cutting busbars with the width from 30-125 mm and the thickness from 5-12 mm. It cuts without deformation and burr. The benders can cut in an axial manner for example the axial bender HSK 5010 or in a lateral manner for example the lateral bender HGP 5010.

|

Busbar processing in E-catalog. |