Cable connectors are often described with the cable terminals, since their use is very similar. The connector and cable terminal should be crimped on the cable. For crimping of both the same Crimpingtools are being used. Crimping methods are also the same. So what is the difference? Cable connectors combine the two wires, and terminal is overmoulded on one side of the cable, while the other has the ending that allows e.g. to connect cable with a screw or cable TV. As already mentioned Cable connector must be overmoulded on the two ends of the wires that connect them together. The right combination, or the pressing is just as important as with cable lugs.

How to crimp electrical connector?

1. Select the correct connector e.g.: type, section, cable material.

2. Then adjust the proper form of pressing, for example: trapeze, square, single indentation. Forms of pressing both for connectors and for terminals are the same. Crimping forms described below can be found in Fig. 1.

Fig.1 Form of crimpings

Table no. 1 Source: http://erko-electro.com/offer/download/technical-data/

- After selectingthe appropriate crimping formfor cable connector it is time for pulling off insulation of the wire. Insulation must be pulled off on the same length as the coupling throat. You cannot forget about cleaning the wire from the oxides or corrosive air raids.

4. The cable shall be placed in the throat of electricalconnector.

5. The next step is selection of an appropriate crimper, which is a crimpingtool for crimping and proper .

How do we know that the crimping is done properly?

The crimping dies must come together with each other or when using a hydraulic device overflow valve works or pump unit. If we are crimping copper or aluminum cable connector according DIN, it should be noted that the place of pressing is clearly marked. The method of marking shows Fig. 2.

Fig. 2. Marking of the place for crimping of copper tubular and aluminum connectors

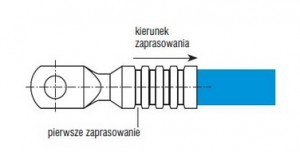

Marking crimping of tubular copper and aluminum connectors. You should note to remember to keep the right direction of hemming. The correct way of crimping cable connector is presented in fig. 4.

Fig. 4. The direction of crimping

Source: http://erko-electro.com/offer/catalog/

ERKO offers its Customers a wide range of cable connectors in different sizes so that it can be appropriately chosen to suit their needs. All products of the highest quality, ensure safe and durable connection with the cable. Couplings may be made of many materials, however, are usually made of copper, aluminum or aluminum-copper. To facilitate finding the appropriate cable connectors, they were divided into categories, most of which coincide with the distribution of terminals categories:

- – Cu tubular terminals and connectors,

- – Al terminals and connectors,

- – Al – Cu terminals and connectors,

- – Shear off screw terminals and connectors 1 – 36 kV,

- – Medium voltage terminals and connectors,

- – Special terminals and connectors.

KLB parallel cable connector, which is used for Cu stranded cables. Made of tin-plated copper, but can be non-tinned at the request of the Customer. Bare of wire cable connector come in 12 sizes from 0.5 to 120 mm cross-section cable. ERKO offer includes both connectors and terminals. Moreover it includes crimping tools and relevant crimping dies.

|

Cable connectors in E-catalog. |