Busbar processing stations are very popular. They are distinguished by high quality and special features which affect on their capabilities. The HG 200 and HD 160 busbar processing stations re very well equipped. Discover their features.

HG 200 busbar processing station is designed for bending and cutting aluminum and copper busbars. Width range of cut busbar is 50 ÷ 180 mm, and bent busbar is 50 ÷ 200 mm. This device is equipped with angle compensation system, consequent to flexibility of bent material. In addition it has ability to use up to 4 bending inserts. This device very simple in use, it has operation panel which minimizing time for programming. Efficient, compact electric hydraulic unit, which has low electricity consumption makes the device very economical. Special worktop shape enables stable bending of long busbars. Following inserts are available:

– cutting HG 205,

– bending HG 201.

For busbar hole punching with cutting option use HD 160. Maximum busbar length is 3 m. This station is equipped with measuring rulers enabling precise positioning of 0,1 mm. Round and oval holes can be punched without burr in incomplete material. Busbar cutting is burr-free and without deformation. Oval holes can be punched parallel or along processed busbar. Please chceck all special features of this station. On request we can also make punches with other dimensions.

Standard dimensions of round hole punches

| Symbol | Hole diameter [ [mm] | For M screw |

| HD 163 – 8,5 | 8,5 | 8 |

| HD 163 – 11 | 11 | 10 |

| HD 163 – 13 | 13 | 12 |

| HD 163 – 17 | 17 | 16 |

| HD 163 – 21 | 21 | 20 |

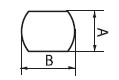

Standard dimensions of oval hole punches:

| Symbol | Dimension A [mm] | Dimension B [mm] | For M screw |

| HD 164 8,5-12 | 8,5 | 12 | 8 |

| HD 164 11-16 | 11 | 16 | 10 |

| HD 164 13-18 | 13 | 18 | 12 |

Busbar processing with ERKO!

|

Busbar processing in E-catalog. |