We manufacture aviation components with use of metal forming and machining.

Most often we make parts of such materials as stainless steel, nickel alloys, copper, aluminium, and brass.

Production of aviation parts, instrumentation, and tooling:

Processed materials:

- stainless steel

- nickel alloys

- titanium alloys

- copper

- aluminium

- sintered metals

Technological processes:

- turning

- milling

- grinding

- cold working of sheet metal

- wet blasting

- Electrical Discharge Machining

- welding

- injection moulding

Computer software:

- EdgeCAM

- NX CAM

- Inventor

- Unigraphics

- AutoCAD

- PC DMIS CAD +++

- PC DMIS VISIO

- Q-DAS q-stat

AS 9100 certified processes:

Machining:

- CNC milling

- CNC turning

Deburring of aviation components

Marking of aviation components:

- Dot Pean Marking

- Electrochemical marking

Cold working of metal parts

Dimensions up to (250 × 300) mm; with the accuracy of 0.2 mm; Max. Press pressure 200 t

- Made of austenitic steels

- Aluminised steel

- Inconel alloys

ISO 9001 certified processes

Machining:

- CNC milling

- CNC turning

Wire EDM machining

Plastic injection moulding machines

Friction welding

Cold working of metal parts

- Aluminium

- Copper

Cutting materials

Grinding

- Flat

- Round

The Aviation Manufacturing Division in Czeluśnica machine park comprises the following:

- 4-axis turning/milling centres

- 3-axis turning centres

- CNC lathes

- CNC vertical milling machines

- Wire EDM machines

- Die-sinking EDM machines

- EDM drilling machines

- Jig drilling machines

- Conventional lathes

- Conventional milling machines

- Shaft and hole grinders

- Surface grinders

- Automatic injection moulding machines

- Friction welders

- Hydraulic presses

- Eccentric presses

- Hardening furnaces

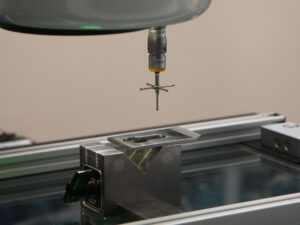

- CM contact optical machines

- CM contact frame machines