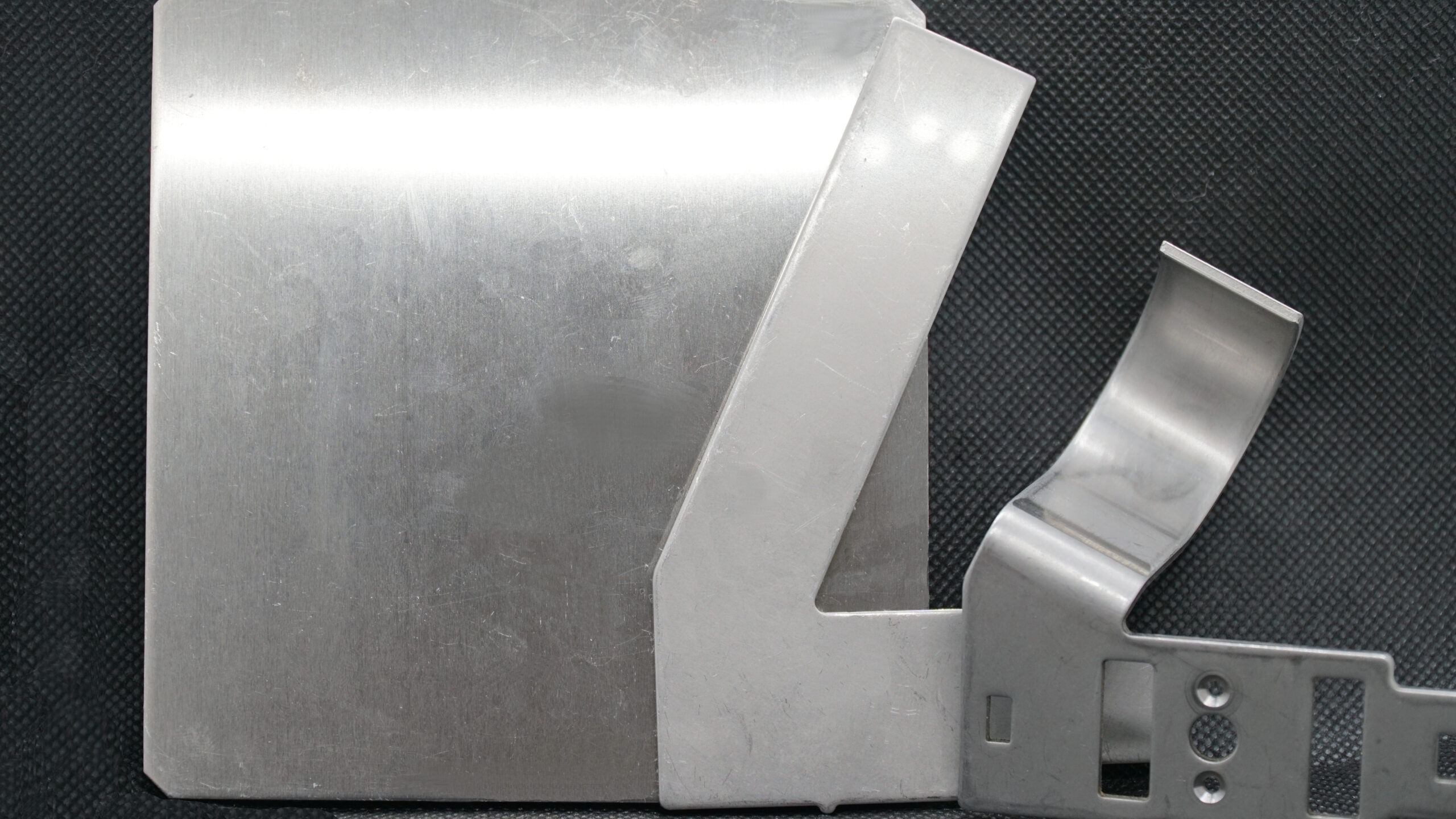

Specialised Sheet Metal Elements manufactured by ERKO

Do you know that ERKO company produces not only tools, terminals, and automatic machines, but it also manufactures individually designed sheet metal elements?

Why ERKO?

40 years of experience

ERKO has been on the market for over 40 years, and it has worked with the aviation industry for 15 years. Now it employs approx. 200 employees, including many specialised engineers and constructors. It is thanks to them that our teams design and create all tooling for production of sheet metal parts.

Owing to our knowledge and experience, we are able to prepare a project with the highest accuracy. We consult the project with the client at every stage of work, introduce changes on an ongoing basis, and propose individual solutions tailored to the client’s needs. We do it all to make sure that it meets customer’s demands prior to launch of manufacturing, during the process, and finally, when it comes to the final product. Trust us and trust the quality of ERKO.

ERKO technology

Innovative equipment

In our projects, we use cold stamping technology that enables shaping of materials with use of mechanical and hydraulic presses. It is an important part of plastic sheet metal processing with the use of press-forming dies, which are specially developed tools, often of complex shapes, the parameters of which are matched to the thickness and stress condition of the metal sheet.

An important aspect is the fact that we design these press-forming dies ourselves, including multi-stroke dies, blanking dies, measuring and welding equipment, all of which can be adapted for automation and robotisation. These tools are thoroughly tested, so that the quality of products is always at the highest possible level. We have presses with working surface with dimensions of 600 mm x 1000 mm and tonnage up to 230 tonnes. Owing to these tools, we are able to implement numerous projects regardless of their scale or weight.

CERTIFICATION

We constantly strive to improve the qualifications of our employees so that they can perform their work at the highest level. The equipment we use is one of the best and most modern in the aviation industry. The quality and safety of the entire production process is confirmed by the AS9100 and ISO 9001 certificates. Our professionalism is also confirmed by the fact that we received the license of the Ministry of Interior and Administration for production for the military industry.

Portfolio of ERKO

Today, we are proud of cooperation with our key partners, including GE Aviation and Pratt & Whitney. These are the leading manufacturers of aircraft engines, and they supply them to such giants as Boeing or Airbus. Our factories produce components for engines used around the world in various variants to power many popular business aircraft. Our cooperation with GE Aviation, a world leader in production of engines for the civil and military markets, is developing very dynamically! We already produce machine and sheet metal elements of remarkably high quality, which can be found, among others in the engines from GEnx generation. These engines propel, among others, Boeing 787 Dreamliner.

Watch the movie about ERKO AERO division

Find out more

We specialize in the manufacturing of aircraft parts with the use of METAL FORMING and MACHINING. We are also a manufacturer of TECHNOLOGICAL TOOLING used in production support, assembly, and measurement.