Discover ERKO tubular terminals

Wondering how to choose the right terminal?

Cu tubular terminals

The ERKO product range includes several types of copper tubular terminals.

Copper tubular terminals can be divided into several different types by:

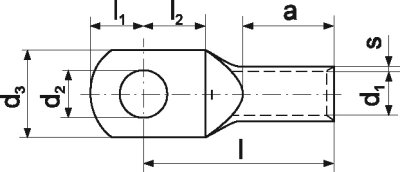

• their manufacturing standard: according to DIN standards (e.g., KCR, KC, KCL) or outside DIN standards (e.g., KCS)

• their shape: flat KCS terminal or angular with 45˚ or 90˚ angle (e.g., KC).

• the number of screw mounting holes made on the contact part of the copper tubular terminal: single or double mounting hole (e.g., KCL terminal); or made according to individual arrangements.

• being dedicated for special purposes: made of other materials or with other galvanic coatings than specified in the existing standards.

• their working voltage: low or medium.

• their manufacturing, e.g., with a tight barrier, as in the case of terminals KCM type.

What makes the ERKO products so distinguishable?

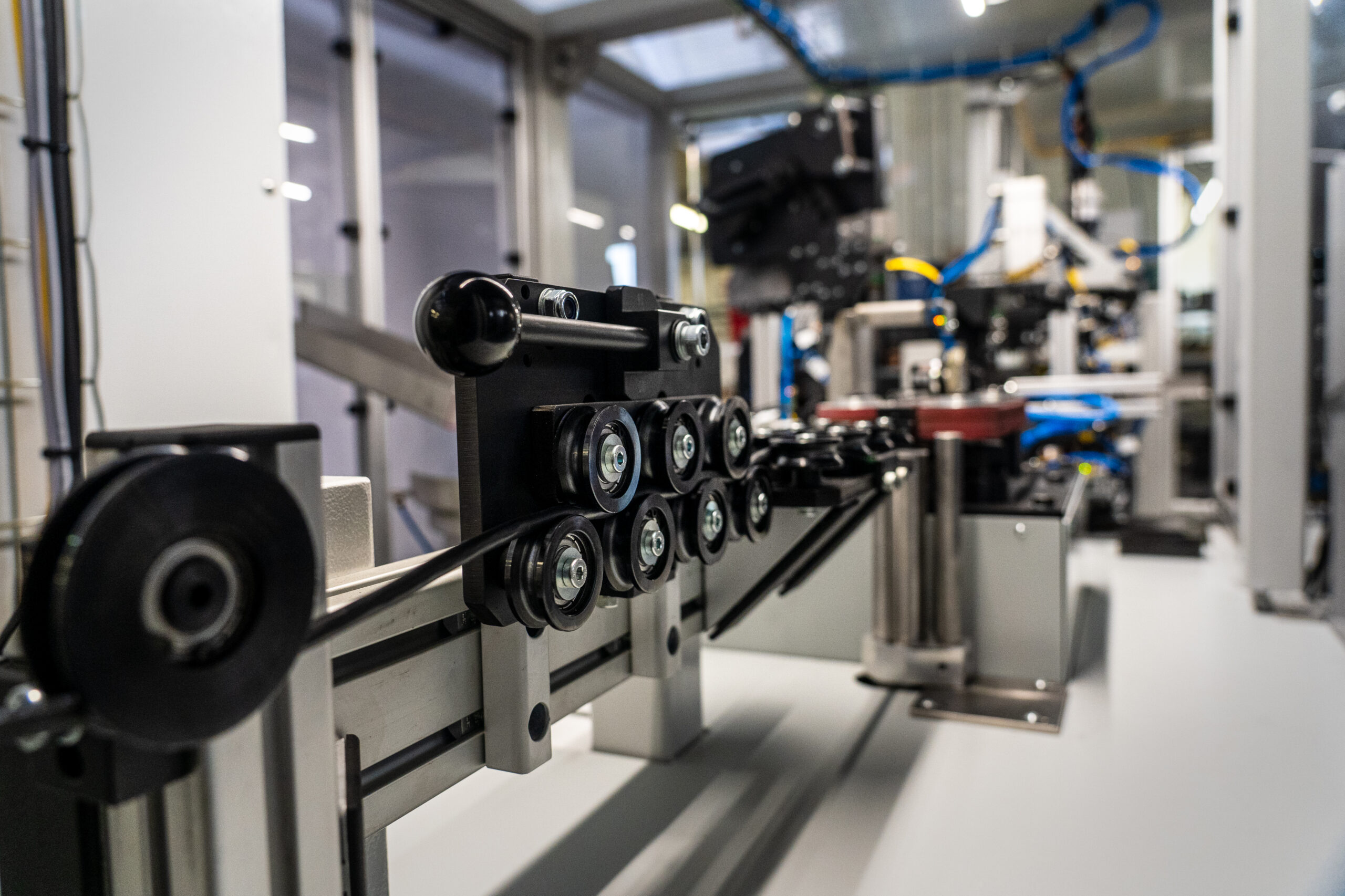

As one of the few manufacturers, for manufacturing of terminals we use galvanically tinned copper of defined parameters (e.g., compliant with DIN standard). Owing to appropriately defined parameters, we ensure long service life and reliability. The tin coating is galvanically applied through an electrochemical process. The galvanic bath has particular efficiency and throwing power, which means a smaller degree of penetration of the inner surface a tube. We have optimized the process of applying the tin coating, where the throwing power ensures minimum 3 μm thick coating inside the tubular part. According to standards, the thickness of coating on cable terminals is defined to be at least 3 microns on the outer surface. We do our best to keep it within the range of 8-10 microns, which is enough to improve the electrical contact and protect the connection of terminal and busbar contact surface from oxidation, etc. The terminals we manufacture also have a higher dimensional tolerance than required by the DIN standard. This feature is very desirable in the automation of the crimping process, as it eliminates jamming of the terminal during feeding and cable application processes.

Depending on needs of industrial customers, we can adjust the terminal to individual needs of a customer, e.g.:

The most popular terminal manufactured by ERKO

The bestseller of our company is the KCS tubular terminal, dedicated for connecting and terminating multi-wire copper cables in the range of from 2.5 mm2 to 400 mm2. It is made of galvanically tinned copper, but on request it can also be manufactured as non-tinned. Chemical composition and delivery of material used for manufacturing of KSC terminals is compliant with DIN 46235 standard (provided for DIN terminals). This guarantees the resistance of terminals to be within the same range as for the terminals made according to DIN standards. The defined delivery conditions of the material from which the terminal is manufactured guarantee that the terminal is properly pressed (no cracks or internal material defects at the area of pressing). This guarantees that the correct resistance of terminal and wire connection is achieved (there is no overheating of the pressing point). The breaking strength of the received connection meets the requirements of the standard in accordance with PN-EN 61238 for the appropriate cross-section of the terminal, determined according to formula: 60 N/mm2. Making sure that the material used for manufacturing of terminals is of the right delivery conditions guarantees that in the process of manufacturing of terminals there are no internal cracks nor delamination of the material, which may result in an increase in the resistance of the connection made and decrease in the required breaking strength.

ERKO sp. z o.o. sp. k.

Lipowa 24 Street

11-042 Jonkowo (near Olsztyn)

Warmian-Masurian voivodeship

phone/fax +48 89 512 92 73

General inquiries: erko@erko.pl

Sales: sprzedaz@erko.pl

Marketing: marketing@erko.pl